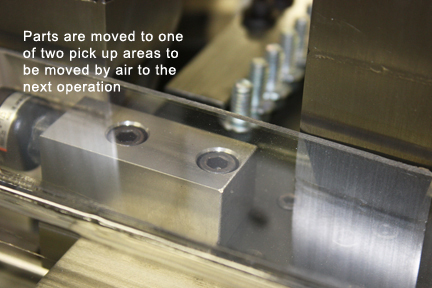

Problem: The customer had an OEM feeding system that moved parts to the next operation with air. The parts needed to be oriented correctly for the next phase of their operations, but their system fed the parts in the opposite orientation. Their system had a mechanism that turned the air driven parts 180 degrees before the parts were sent down the line. However, the turning mechanism failed often and was the source of considerable down time.

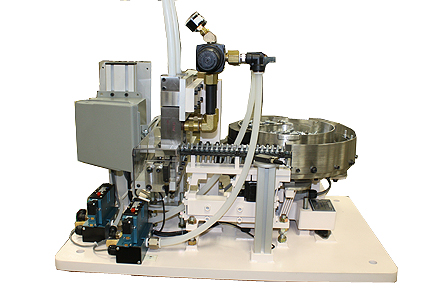

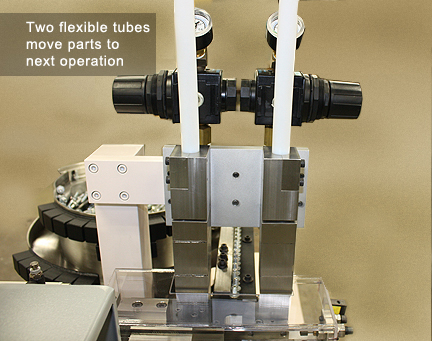

Solution: Fortville Feeders came up with a vibratory feeder bowl that sorted and properly oriented the parts down a horizontal track. The parts were then singulated and moved alternately to two flexible air tubes. Fortville used a vacuum pick up to send them to the next operation properly oriented. This allowed the customer to shut down their old turning mechanism. It saved them valuable production time and frustration.

Recent Comments