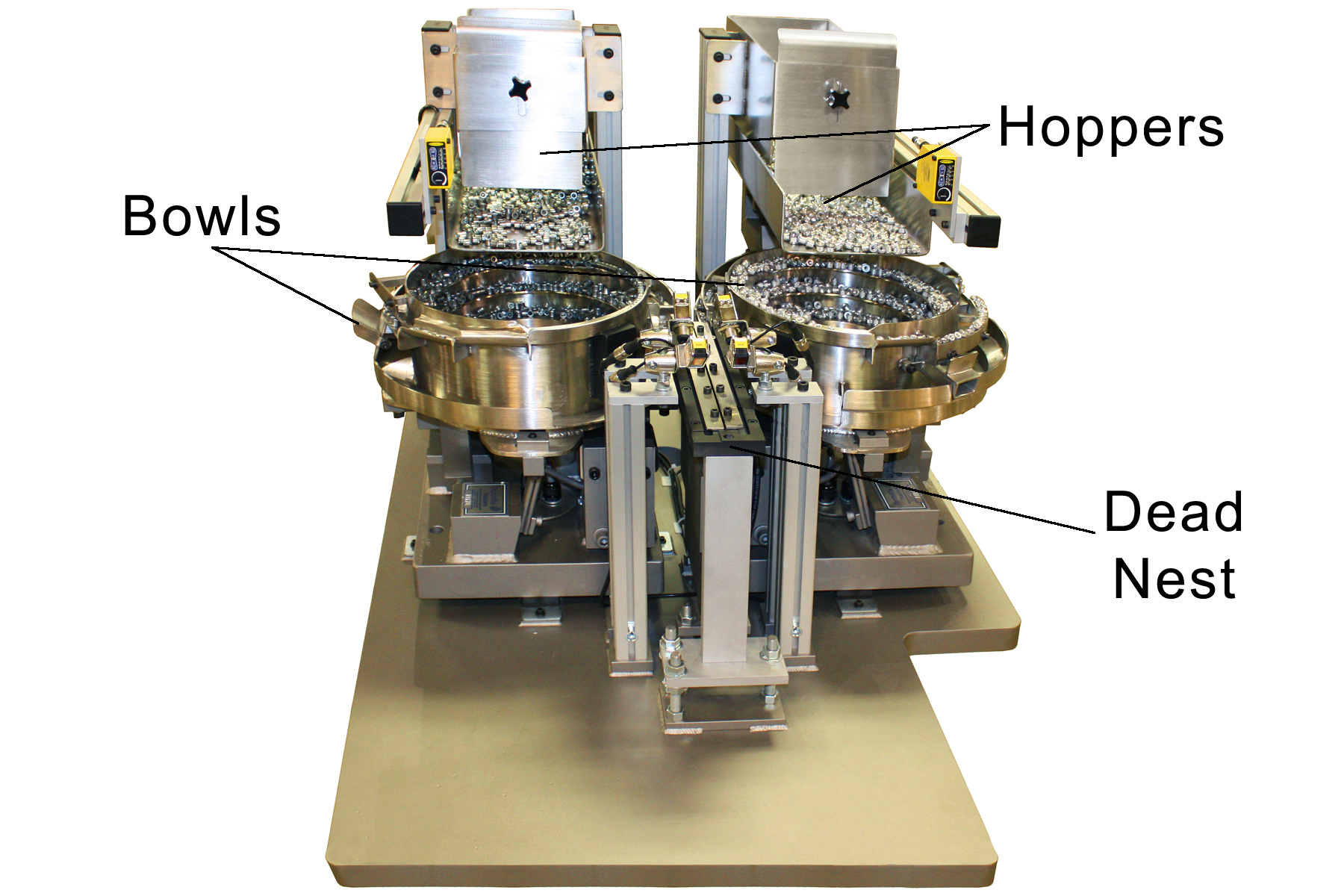

Problem: This customer needed to have an efficient way to feed two parts – a bushing and an insert – to a common dead nest for pick- up with their robot.

Solution: Fortville built a dual vibratory feeder bowl system that fully automated the loading of parts into their machine. Each system had a vibratory hopper that continually fed parts into the bowls. Parts were then aligned and fed into a single dual pocket dead nest, where they were picked up with the customer’s robot and fed to the next process. The customer was able to pour bulk parts in one end and attain a finished part at the opposite end, thus saving valuable time and eliminating human steps in this process. The system eliminated human error of parts being placed in the wrong bowl or mixed with the other parts. Each bowl had a mixed part rejection chute built into the system.

Recent Comments