Problem: The customer wanted to redesign a three part feeder system. The three parts would be picked up and assembled by a robotic gripper arm. It was important that the new feeder system save space, be able to work with their robot, and be able to match the finish of their other equipment.

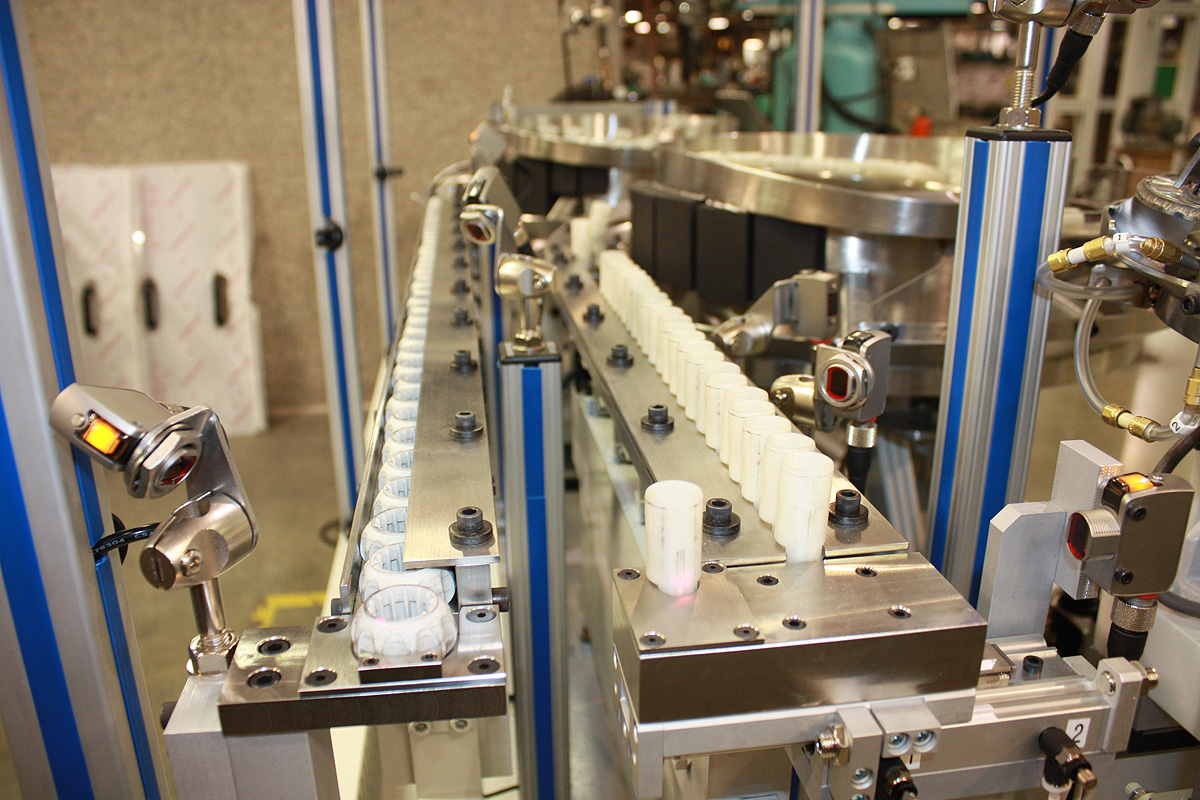

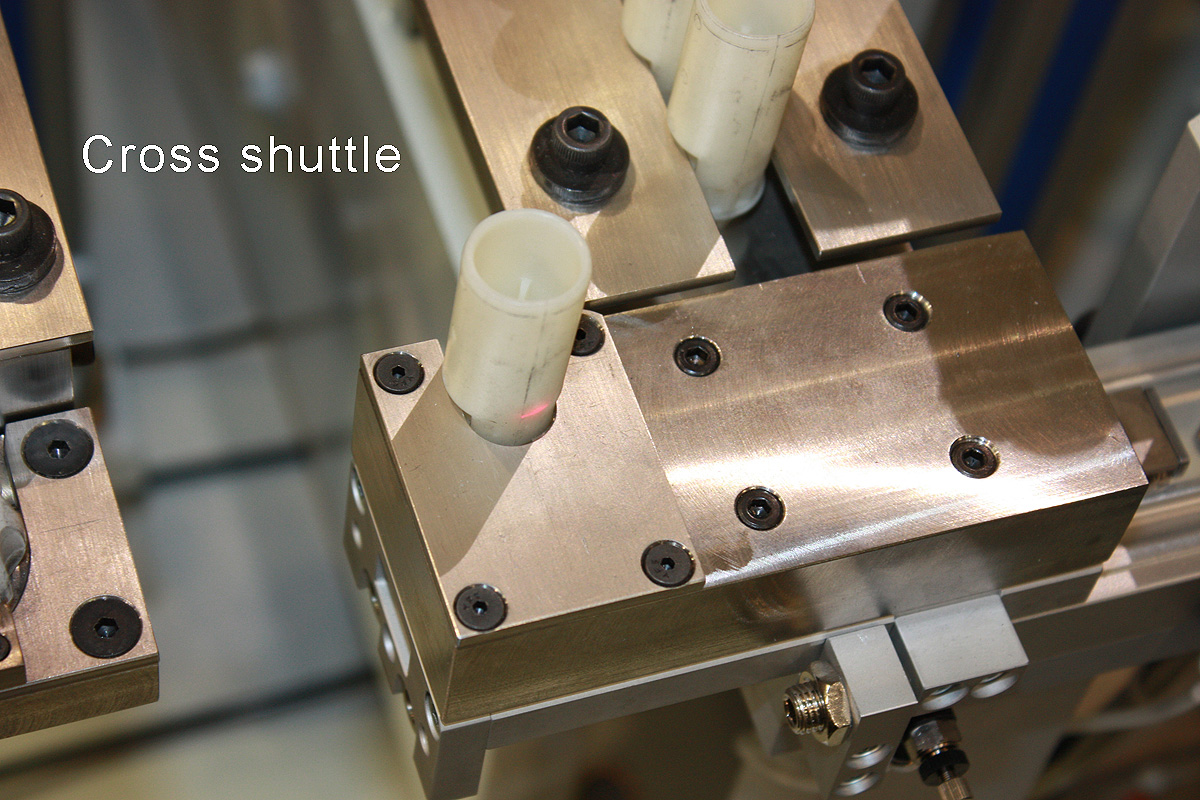

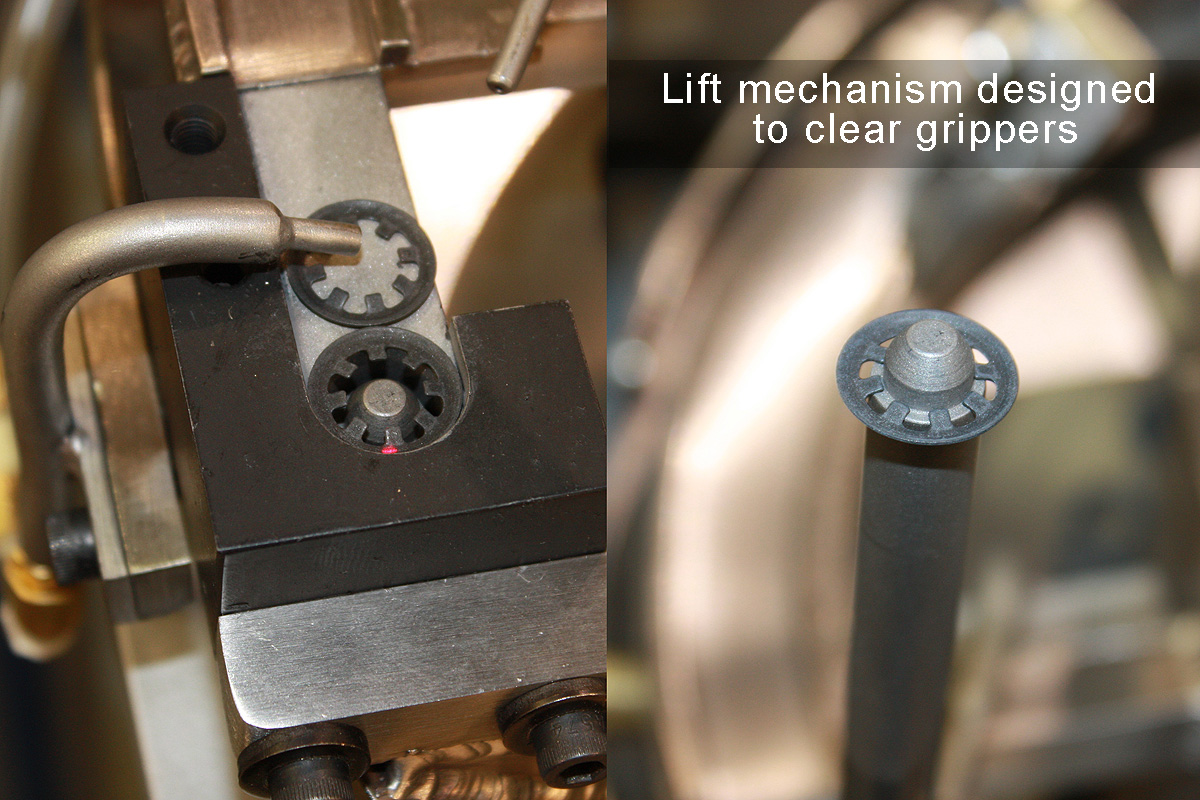

Solution: Fortville Feeders designed a compact three bowl system that isolated the parts for a single pickup point. The bowls were enclosed in a single sound barrier to limit production noise and keep airborne dust from the parts. The parts were moved down line to the robot. The first part was picked up in a dead nest. The second part was moved into place over the first part with a cross shuttle. The third part was picked up on a lifting mechanism that was timed to clear the gripper arm. The compact size of the feeder system helped to increase production output. With a single point of pickup, it limited the travel distance for the robotic arm. The compact design saved space on the production floor. Also, Fortville was able to match the finish of the other automated equipment. The new feeder system was aesthetically uniform with the rest of the floor.

Recent Comments