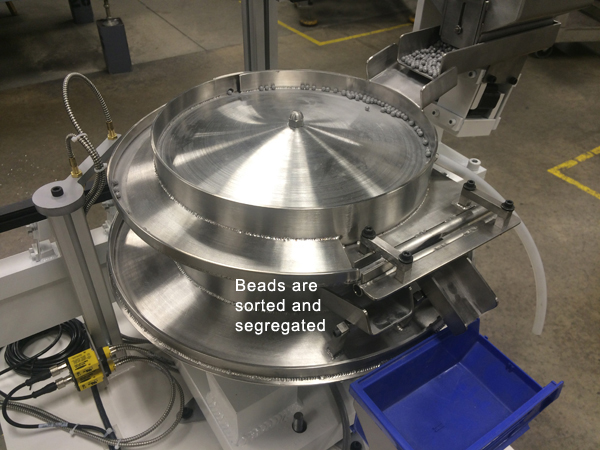

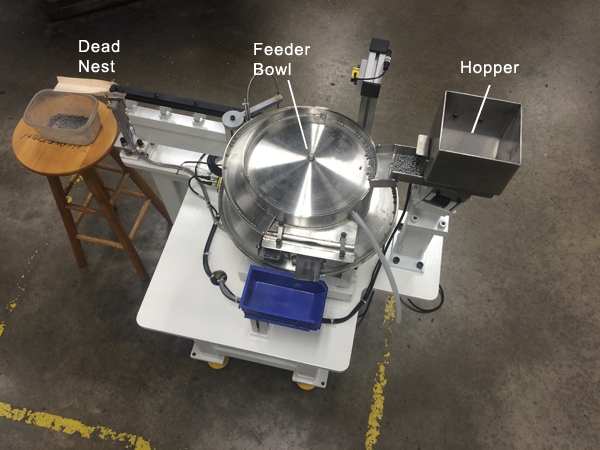

Problem: The customer was working with two different sizes of braze beads that they wanted to sort and feed down an automated line. Solution: Fortville built a bulk hopper that fed the beads into a vibratory feeder bowl. This allowed the operator to load both sized beads into the same hopper and the system segregated them. The beads were moved down an inline track to an escapement device that sorted the beads for size. The beads were then moved to a dead nest for pickup. The system could be adjusted for the different sized beads with no turnover time required.

Recent Comments