Problem: The customer was packaging prophy angles that are used in dentists offices for teeth cleaning. They wanted a feeder system that would run a dual line for their bagging systems. Each line would be required to feed up to 200 parts per minute.

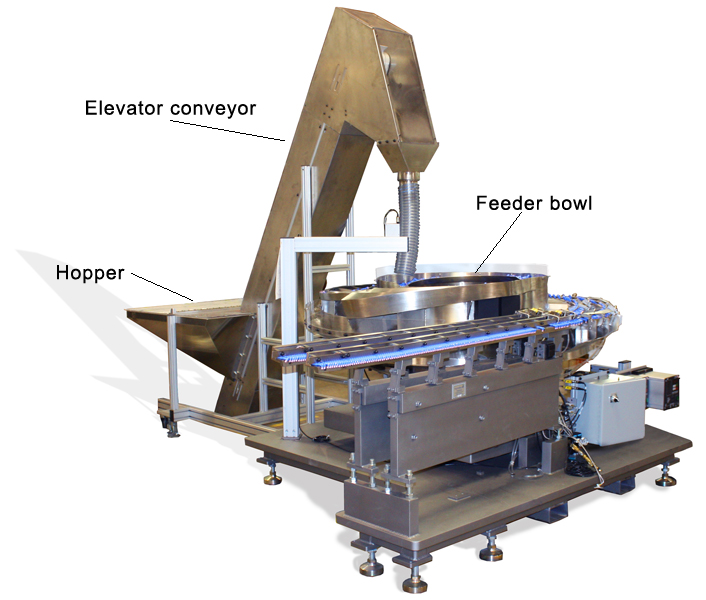

Solution: Fortville’s design engineers provided the customer with three system concepts. Each design exceeded the requirements of the job and fit the space needs of the manufacturing facility. The customer decided to use a low profile hopper with an elevator conveyor system that fed a vibratory feeder bowl. The bowl aligned the prophy angles and sorted them into two lines, which dropped into a rapid bagging machine. The system was designed to feed multiple parts with minimal changeover. Fortville was not only able to build a system that could exceed the feed rate by 10% over the 200 ppm specifications, they also were able to do it with a system that took up half the space as other systems. This savings of space freed up additional floor room for other operations.

Recent Comments