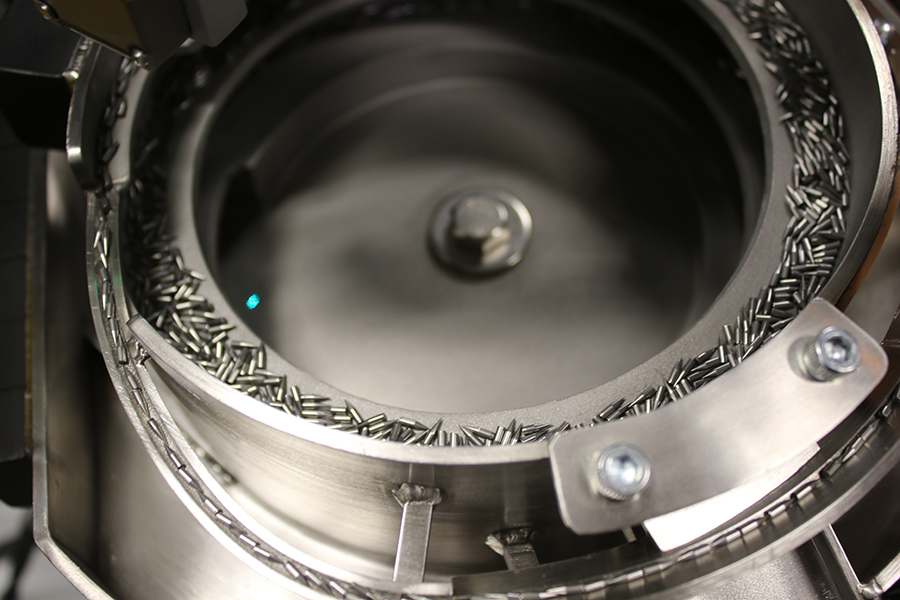

Problem: An integrator needed an automated parts feeder for metal pins. These pins were very tiny. The pins had to be oriented with the point facing forward for the next operation. These tiny pins were difficult to orient and singulate. On top of that, the customer needed a parts handling system that would run three different parts, all of varying lengths.

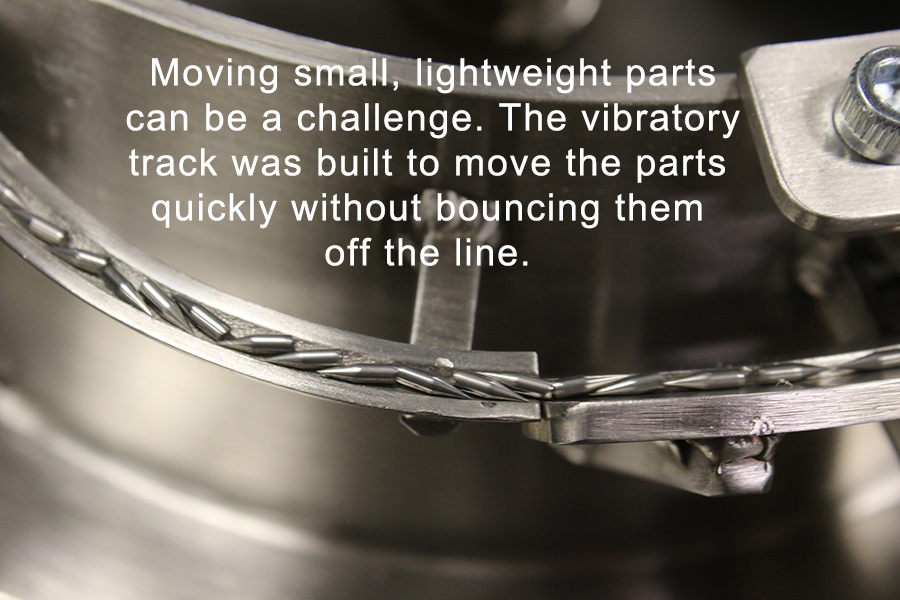

Solution: Fortville Feeders provides engineered solutions for difficult parts handling problems like this. In this case, the parts were not only tiny, but were also lightweight. Excessive vibration or air movement can cause parts to bounce or fall from the track in this type of situation. The vibratory feeder was regulated to keep parts moving without shaking all of them off the line.

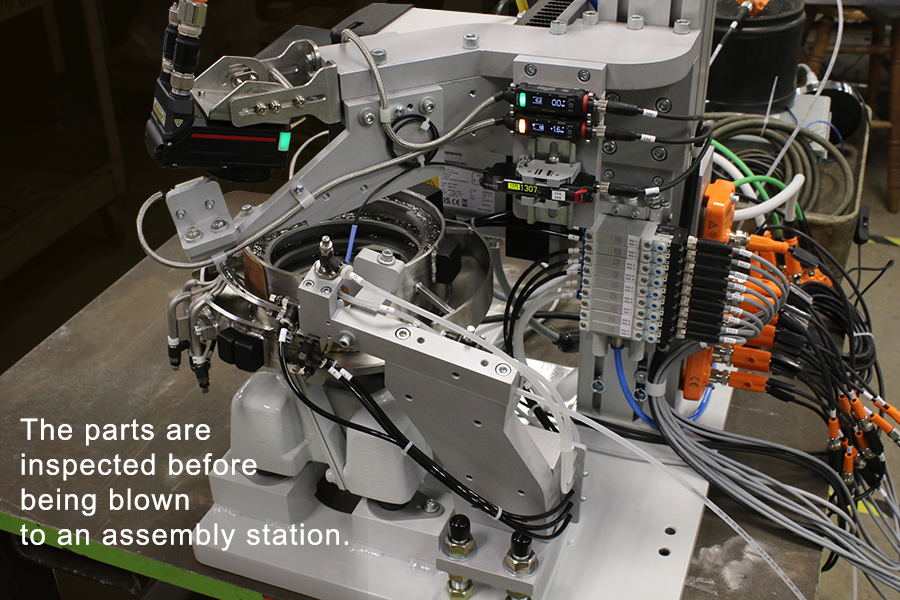

The system was designed to move the parts to an inspection station with a vision system. The camera read each part to ensure it was oriented with the point forward. Noncompliant parts were sent back to the feeder bowl via a return pan. The system was built with very tight tolerances in the track to hold each part in place. As each part was singulated, it was sent to the next operation via a pneumatic blow-feed tube.

The automated parts feeder was also designed and built to quickly changeover from one part to the next. Fortville builds vibratory parts feeders to empty quickly and adjust the tooling for the new part in a matter of minutes. In this case, the system could be emptied and readied for the next part in two minutes.

If you are looking for an engineered solution for difficult parts handling situations like this, contact Fortville Feeders.

Recent Comments