FLEXIBLE PARTS FEEDERS

We offer a variety of Flex Feeders that are programmable, vision-based solutions that easily integrate with your robots

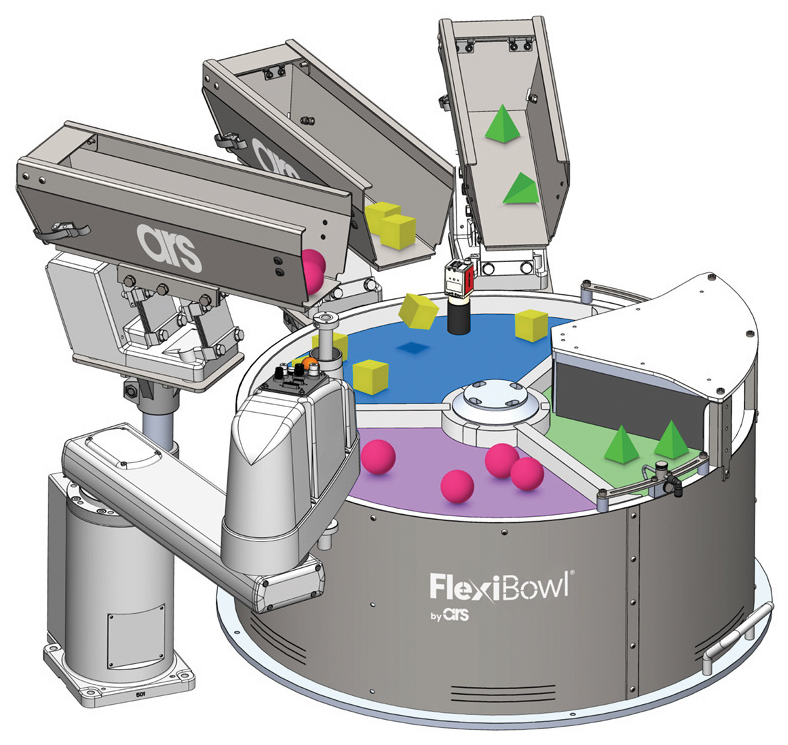

FlexiBowl® flexible parts feeders are designed to handle multiple, complicated parts with speed and precision

FlexiBowl® is the flexible parts feeding system for automated production lines using industrial robot or cobots. It is patented and produced by ARS S.r.l.

FlexiBowl® optimizes parts feeding by ensuring more parts are available for pick-up by the gripper in every cycle. The system improves overall feed rates, increases productivity and reduces changeover times.

Parts Size: Up to 10"

Weight: Up to .5 lbs

Simultaneous multiple parts feeders (up to 6 different parts)

Benefits:

- High speed (>90 parts per minute)

- Cleanroom certified (ISO 5)

- Custom feed surfaces

- Plug-ins for all major robot brands

- Cognex integrated vision software

- Integrated back-lighting or top-lighting

- Simultaneous multiple parts feeding

Not sure which feeder to choose? Send us your parts and we will make a recommendation.

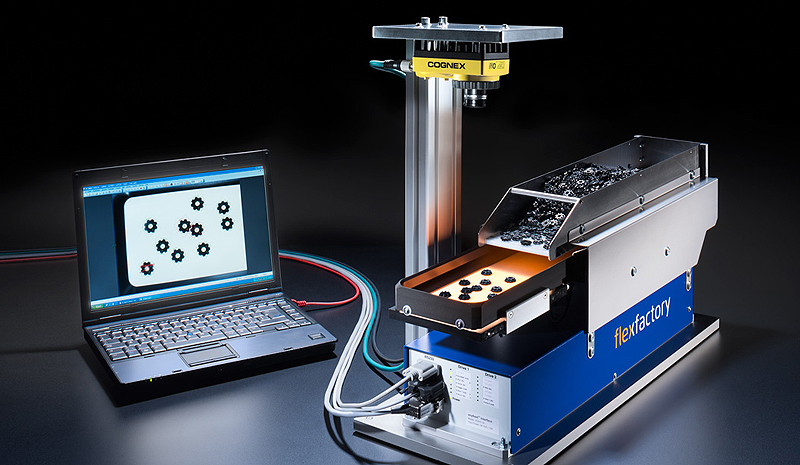

Parts Size: Up to 4.5"

Weight: Up to .16 lbs

110 Vac

FlexFactory® with vision systems for robotic manipulation and recognition

Perfect for small, complex and delicate parts. Handles multiple parts with no down time for changeover. Automatically recognizes and correct part orientation.

Benefits:

- Integrates with your current robots and software

- Works well with systems that have frequent parts changes

- One button, quick-empty mechanism

- Quick change feed plates

- Integrated bulk storage bin

- Gentle parts handling

Not sure which feeder to choose? Send us your parts and we will make a recommendation.

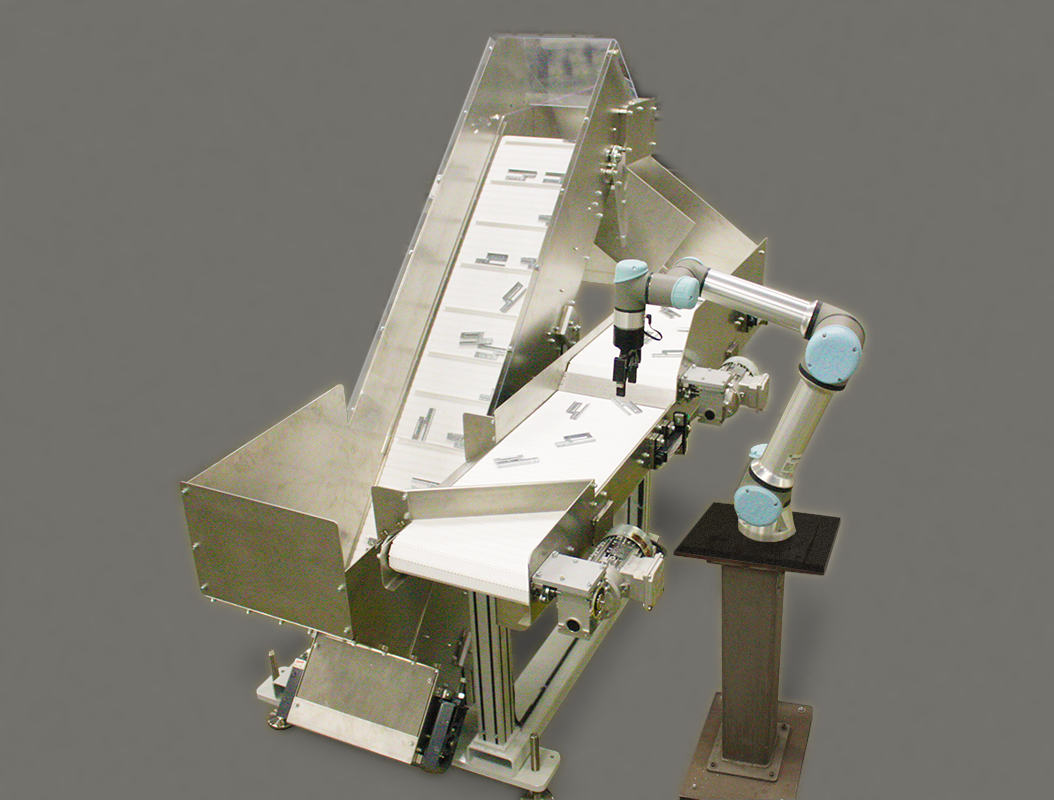

Parts Size: No limitations

Weight: No limitations

110 Vac

Return-to-Hopper Flexible Feeders handle parts of any weight, size and shape

Fully customizable to handle multiple parts at any speed. Handles parts that are difficult to flip with a constant recirculation of misoriented parts.

Benefits:

- All components stocked or manufactured in-house and available for time-saving design/build

- Hopper, elevator, chute and conveyor all customized to parts’ dimensions and handling specifications

- Optional pre-programmed robot and camera

- Can be configured to handle multiple parts simultaneously

- Let us take care of the details: Belt and cleat dimension, gear motor size/speed, hopper design, part spacing, etc.

- Designed for easy maintenance

- Quick discharge chutes

Not sure which feeder to choose? Send us your parts and we will make a recommendation.

Find a representative

In an Area Near You

We provide sales support across the United States. Find the Representative that services your area.