Problem: Metal springs are notoriously hard to feed with automated systems. When handled in bulk, they tend to get tangled. An integrator needed a parts feeder that would deliver 210 metal springs per minute. To do so, the parts handling system also had to detangle the bulk springs.

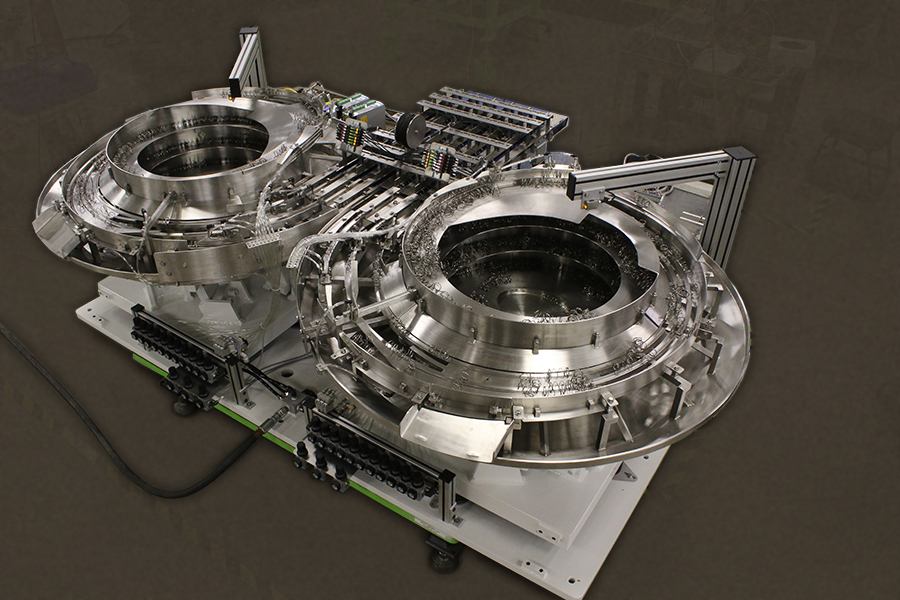

Solution: Fortville Feeders specializes in complicated automated parts feeding solutions. In this case, the customer needed six lines to feed their assembly stations. Fortville designed and built a dual-bowl parts feeder that separated tangled springs as they moved through the bowls. If springs continued to be tangled after the initial detangling station, they were dropped off the line and returned to the bowl for recirculation.

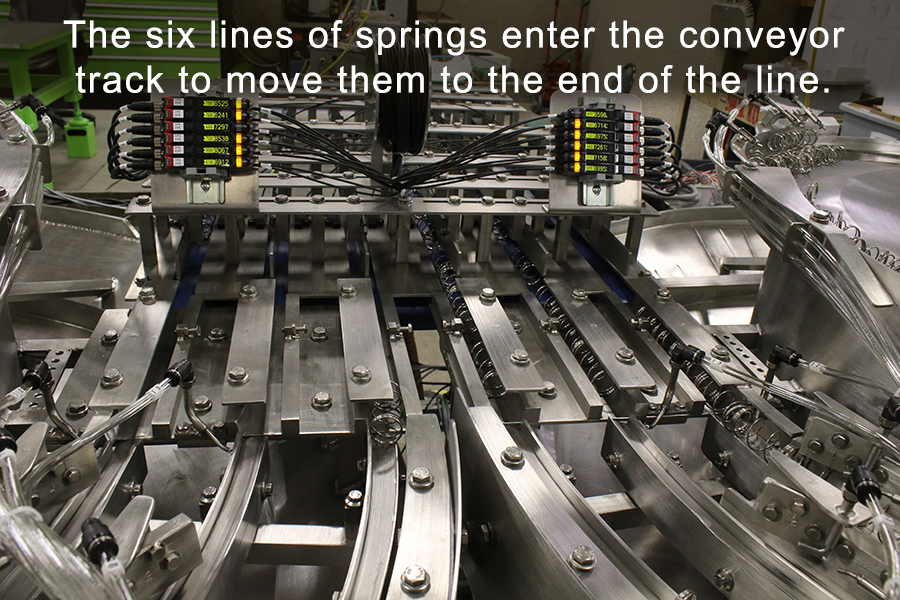

Each spring was then oriented as it moved toward the track. A vibratory track fed a conveyor track. The six lines were designed to keep the springs separated and moving quickly to the end of the line, where they were picked up for assembly.

Fortville was able to build a parts handling system that effectively solved the detangling problem and kept parts moving per the customer’s specification.

Recent Comments