by Kevin Yaney | Feb 5, 2024 | Escapements and Mechanisms, Featured

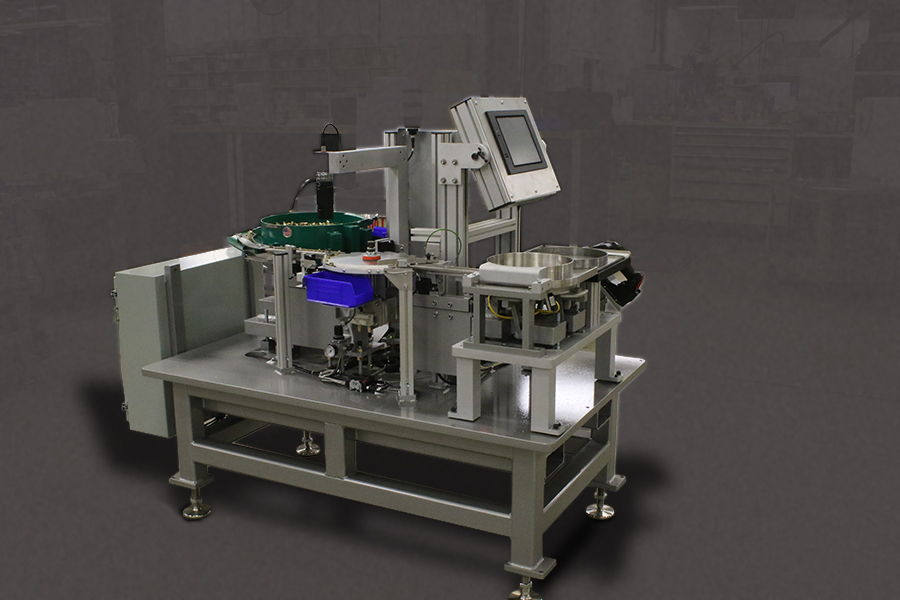

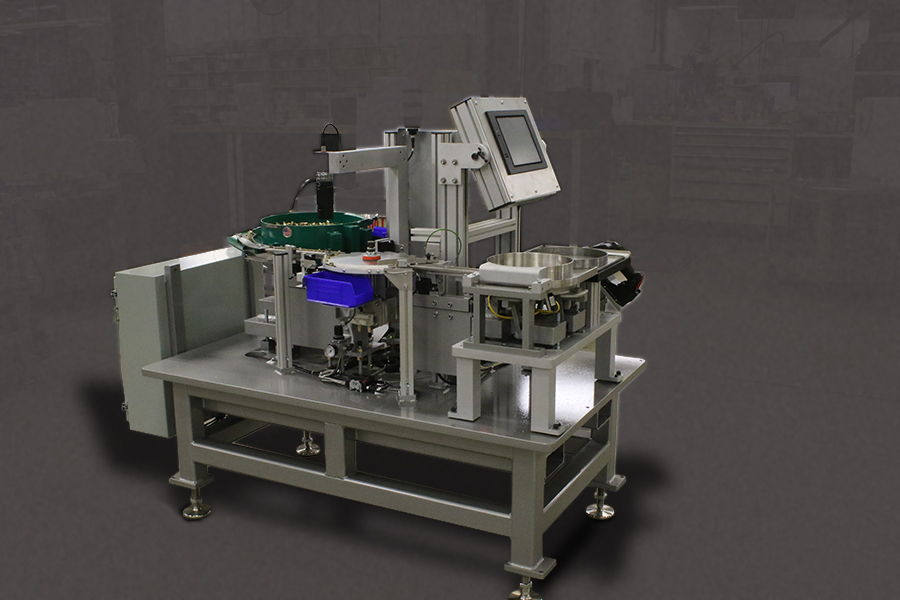

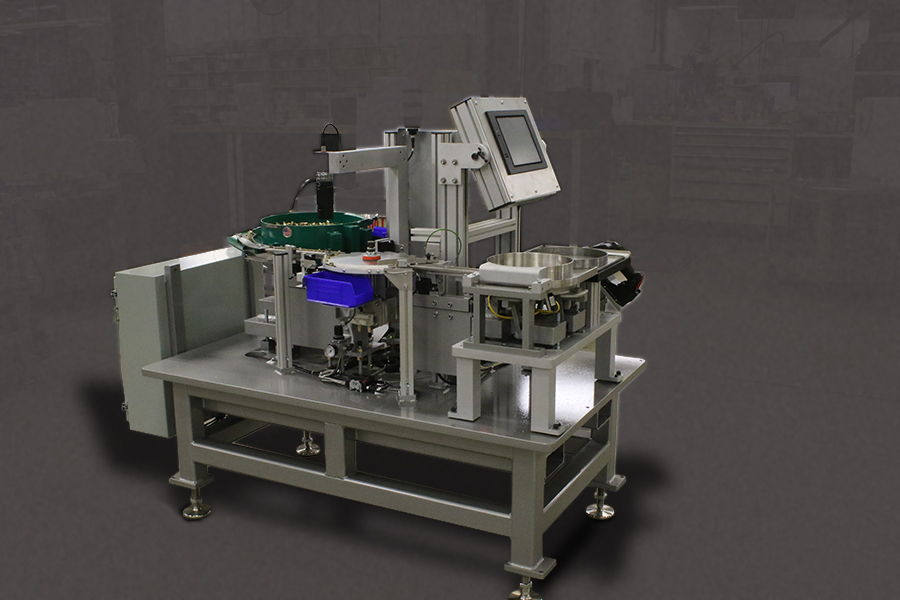

Problem: A manufacturer was using a two-step process to inspect and accumulate parts prior to the final machining operation. The process required double the manpower and introduced possible errors by mishandled parts. Each part was presented to a camera and another...

by Fortville Feeders | Sep 1, 2023 | Featured, Feeder Bowls

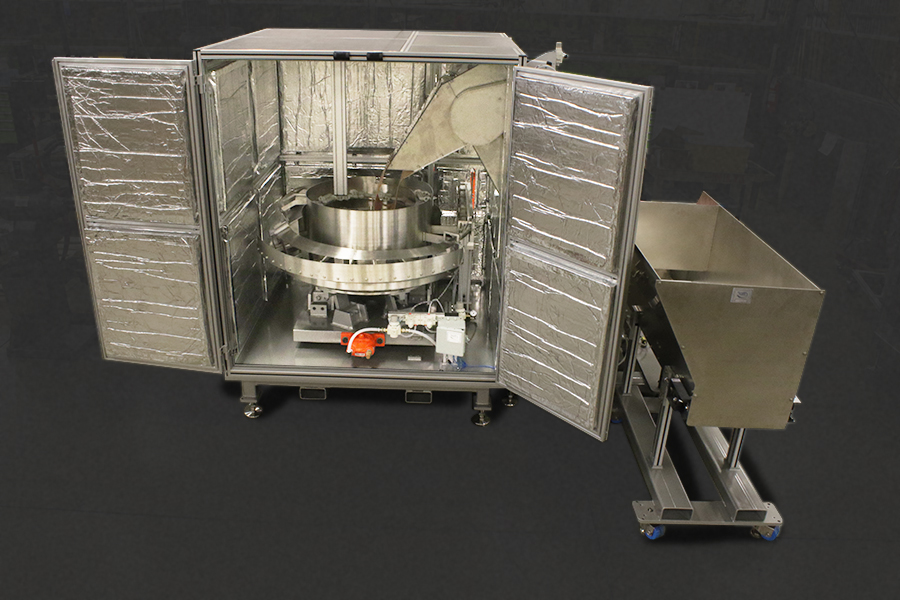

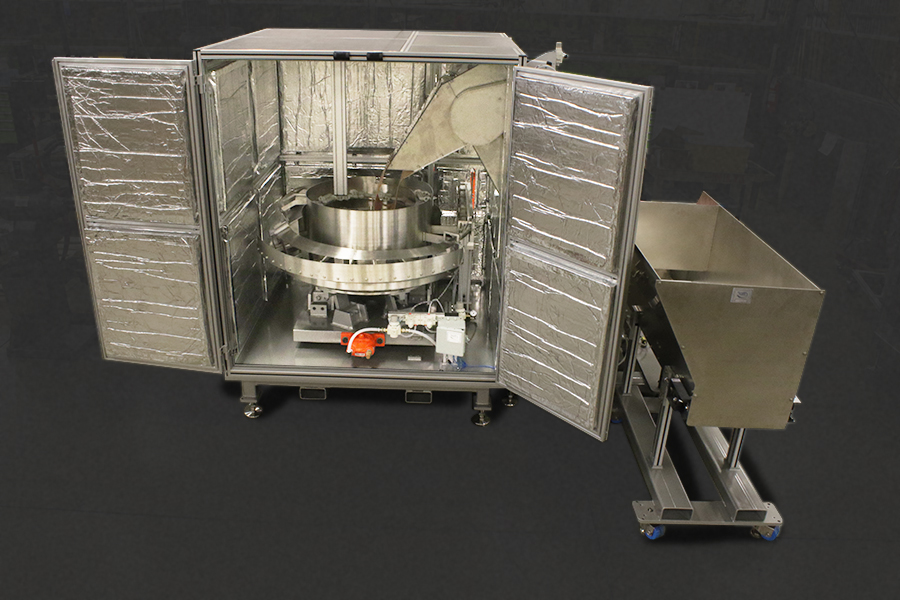

Problem: A manufacturer of syringe filling machines needed a complex parts feeding system. They were designing a system for operations in a C1D1 manufacturing environment where highly flammable and explosive material was being used. That required no electrical wiring...

by Fortville Feeders | Jun 22, 2023 | Featured, Tracking Systems

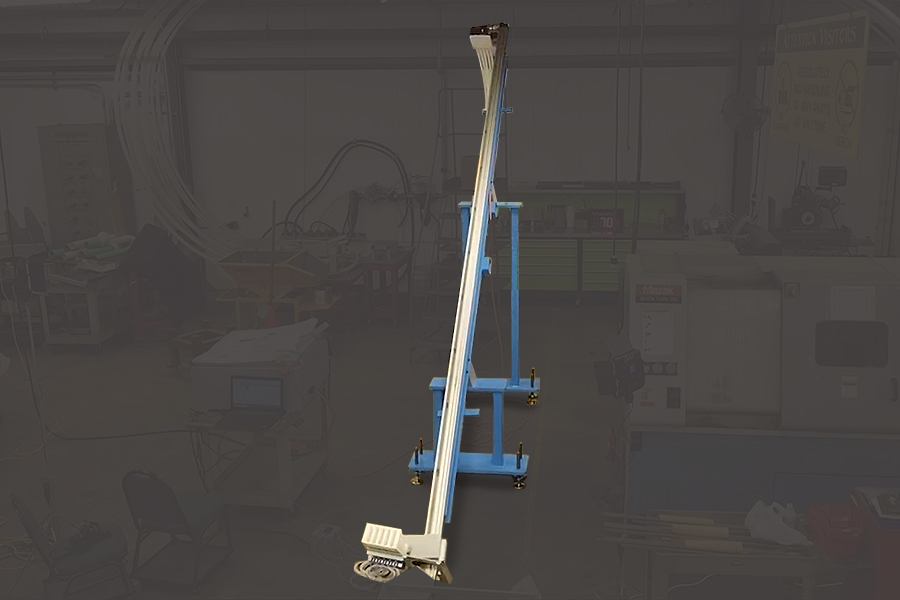

Problem: The manufacturer of auto parts was looking for a new parts feeder solution for an assembly cell. Their engineers had designed the assembly cell with a dead nest to handle four parts, which were assembled and placed on a conveyor. This required the parts to be...

by Fortville Feeders | Dec 20, 2022 | Featured, Hoppers

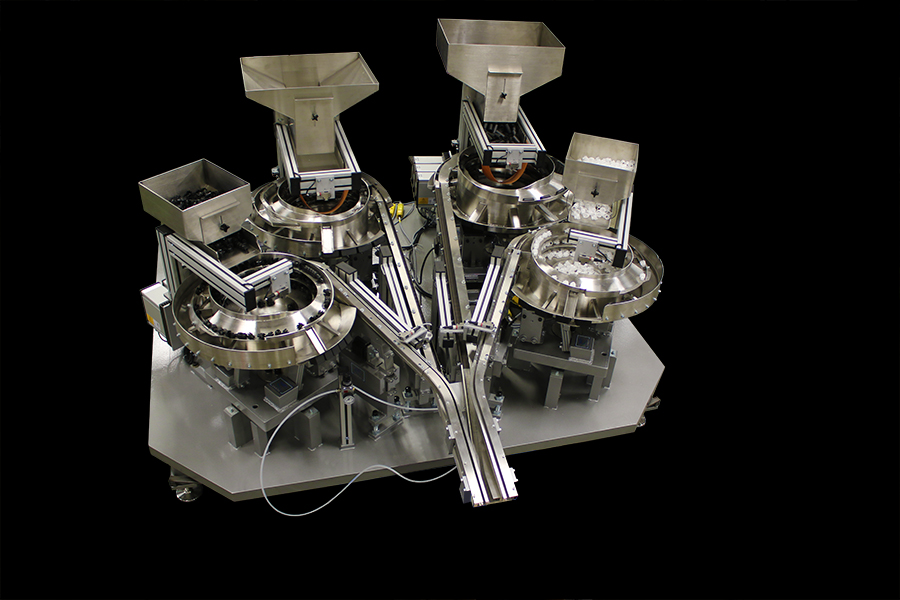

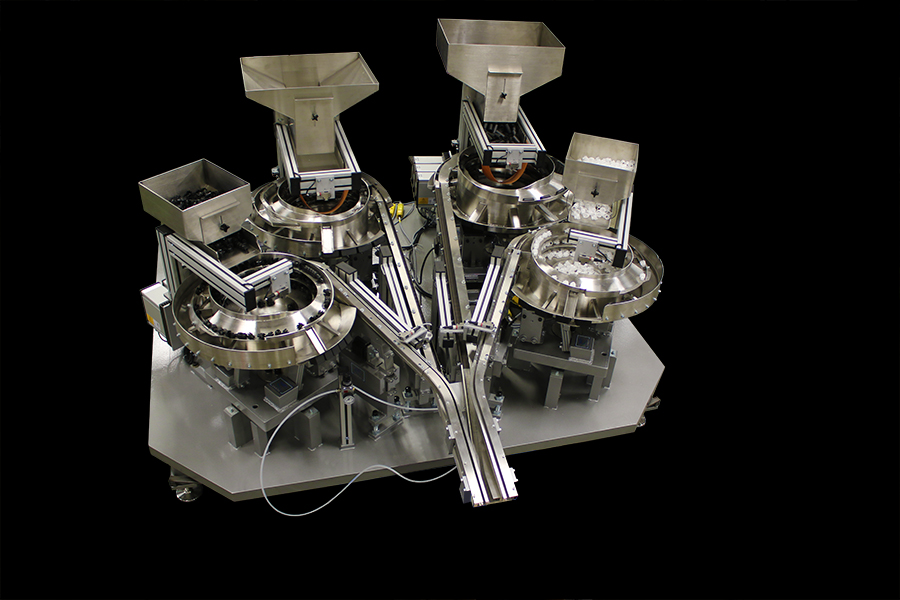

Problem: An integrator was building an assembly station that used four different parts in a hydraulic fabrication. They were looking for a parts feeder that could feed all four parts to an assembly cell. However, there were some unusual safety constraints. For safety...

by Fortville Feeders | Oct 6, 2022 | Featured, Hoppers

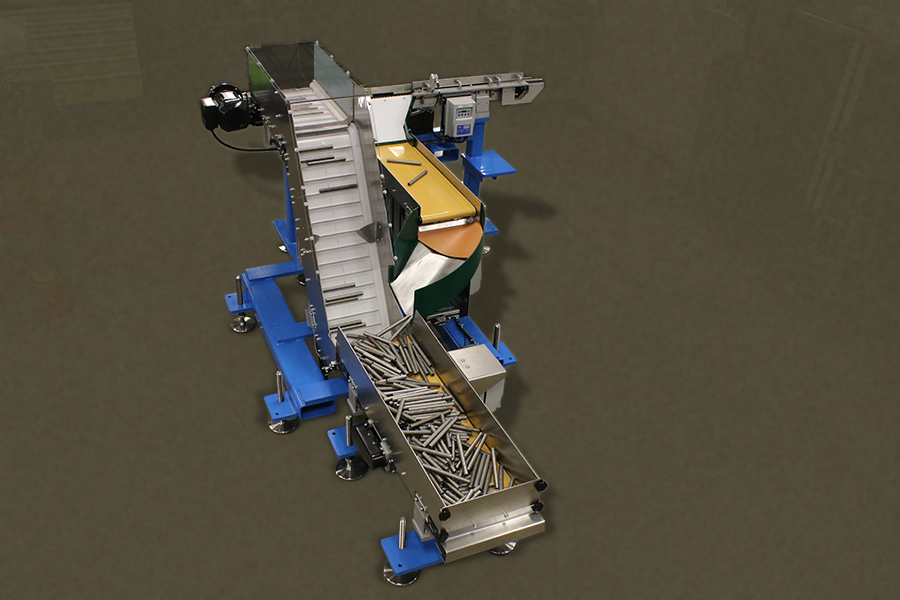

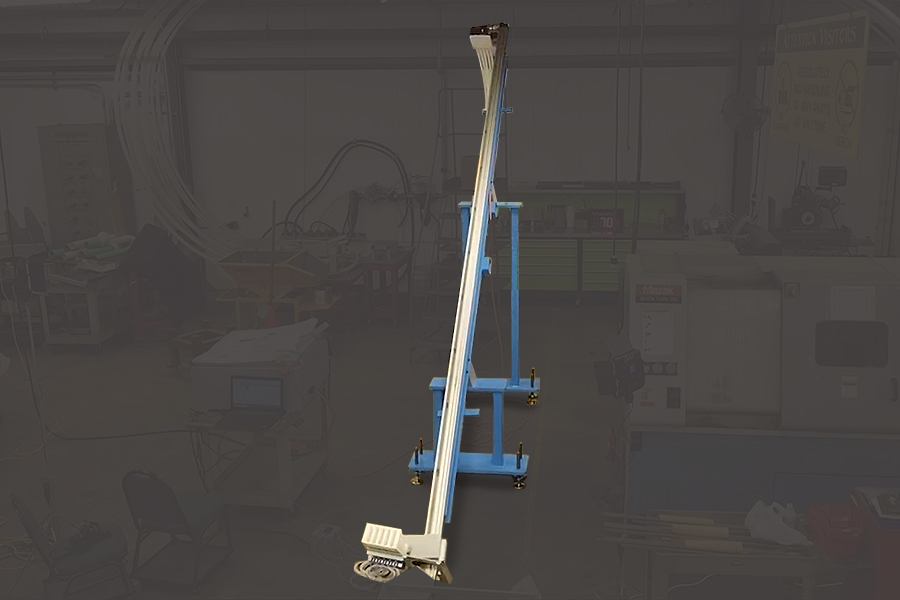

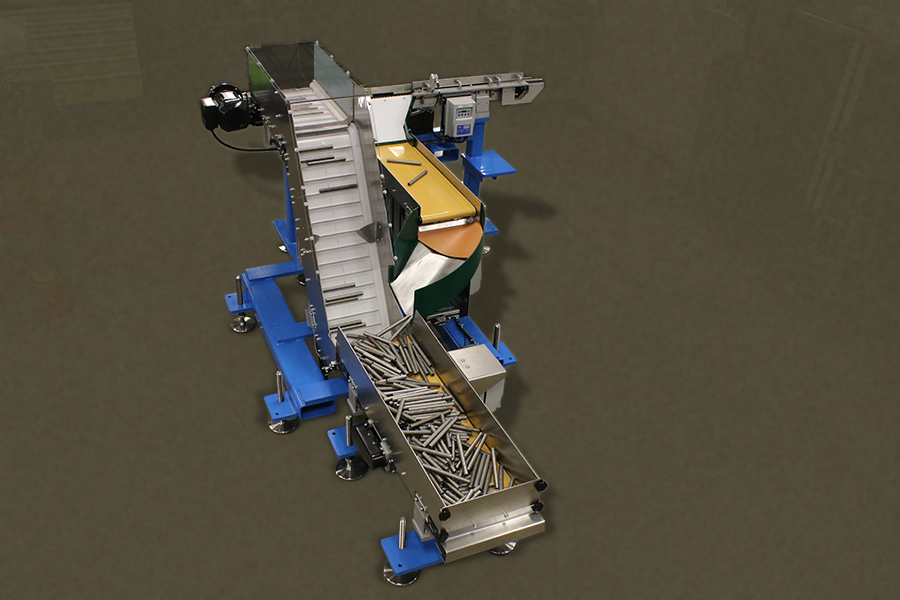

Problem: A manufacturer of wheel assemblies was facing a problem with the parts feeder that pneumatically moved wheel studs to an assembly station. The studs were moving at a high speed due to their weight and the distance needed to move them to the station. This...

by Fortville Feeders | Aug 15, 2022 | Featured, Feeder Bowls

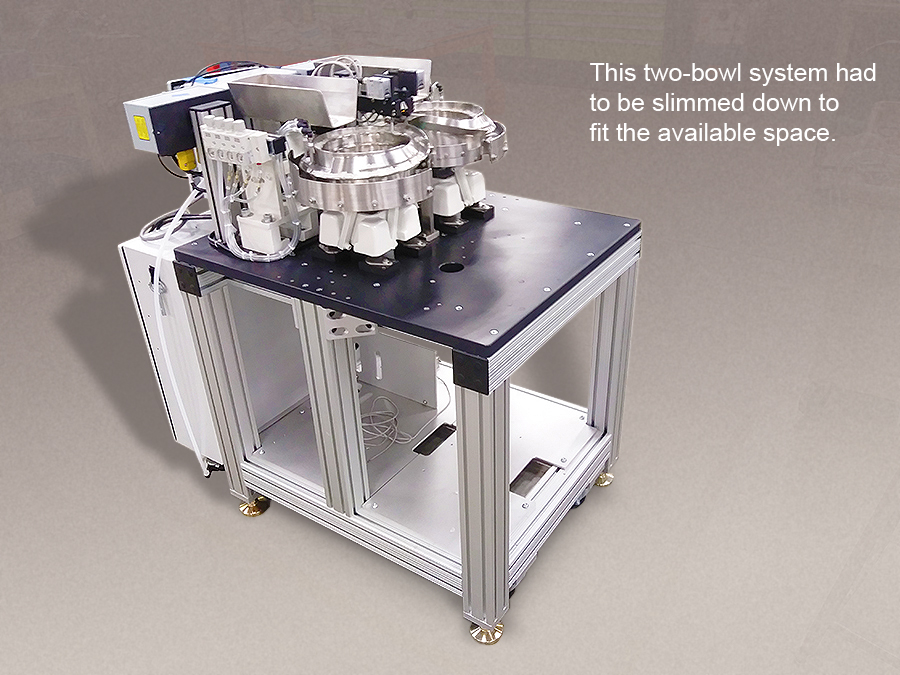

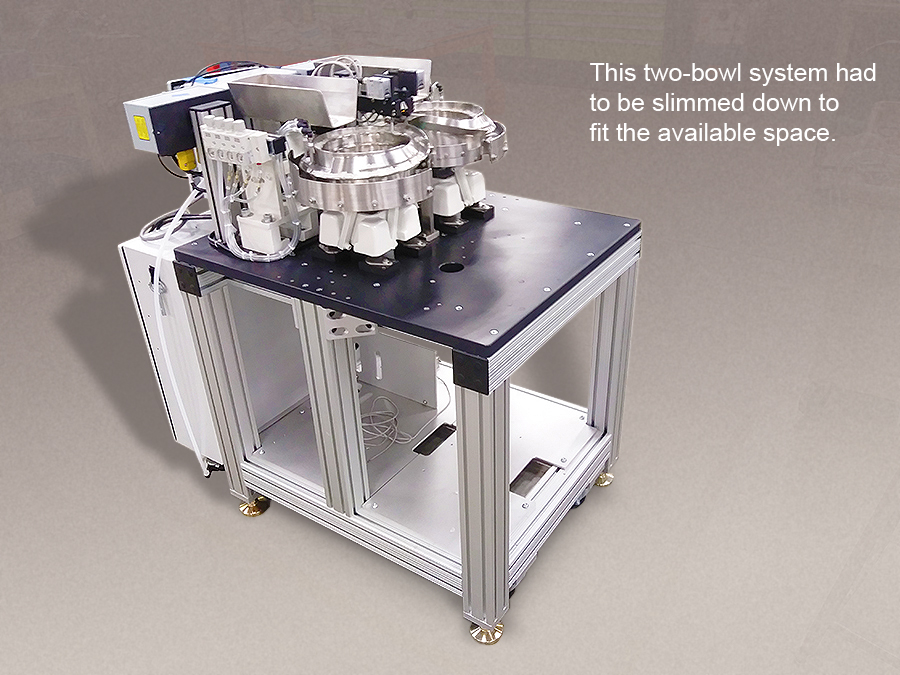

Problem: An integrator was building an assembly system that handled 64 different flat rubber seals. There were very tight quarters for the machinery, especially the feeder system. The space was so tight that the standard-sized feeder equipment would have to be sized...

Recent Comments