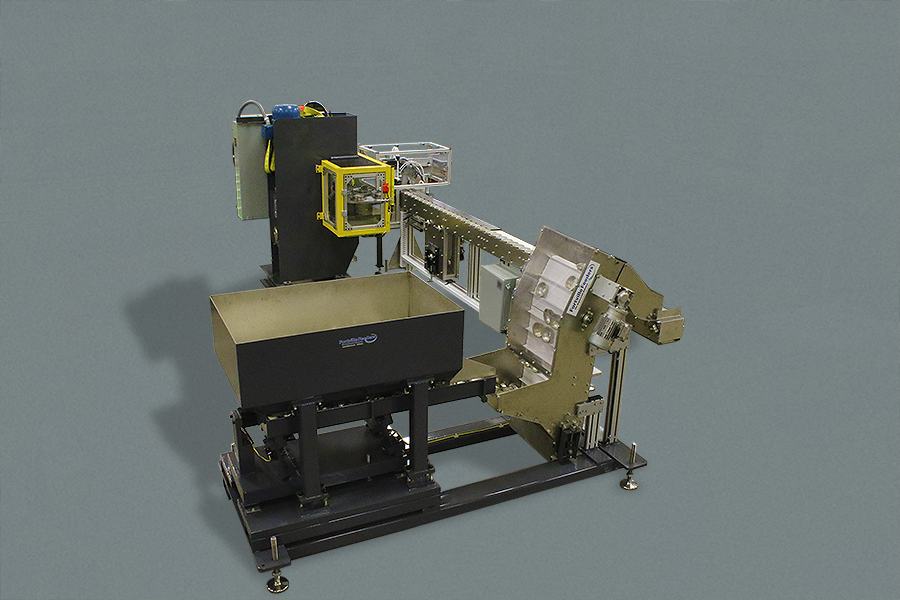

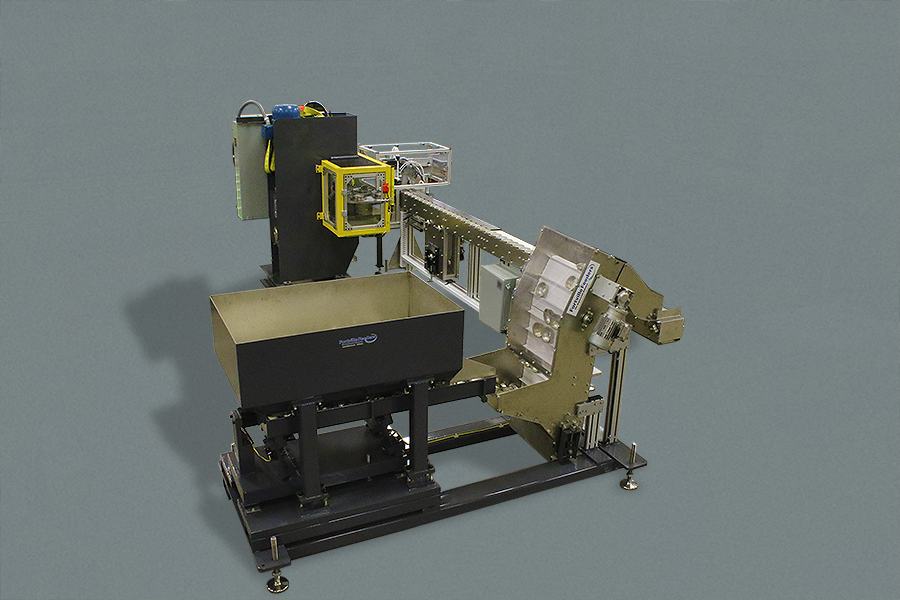

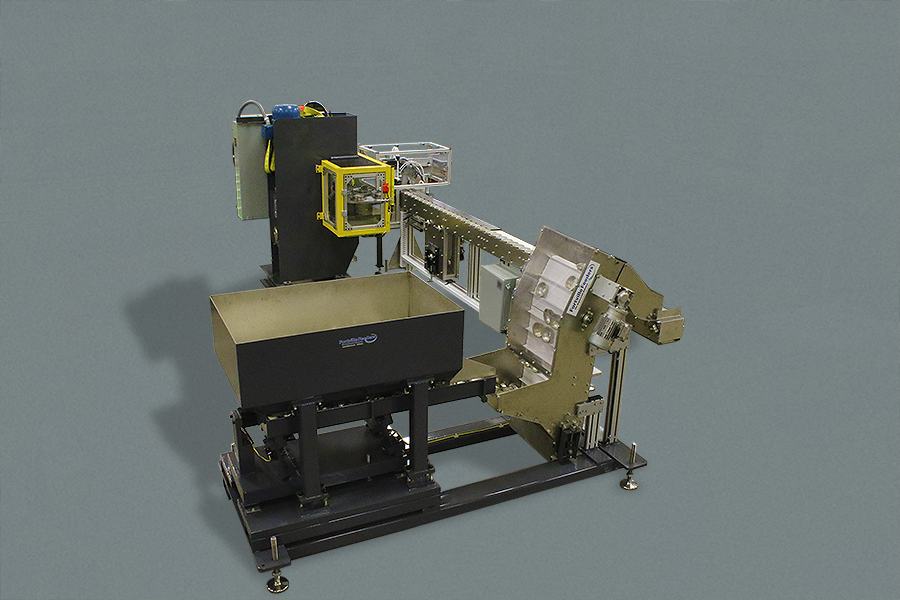

by Fortville Feeders | Sep 26, 2023 | Escapements and Mechanisms

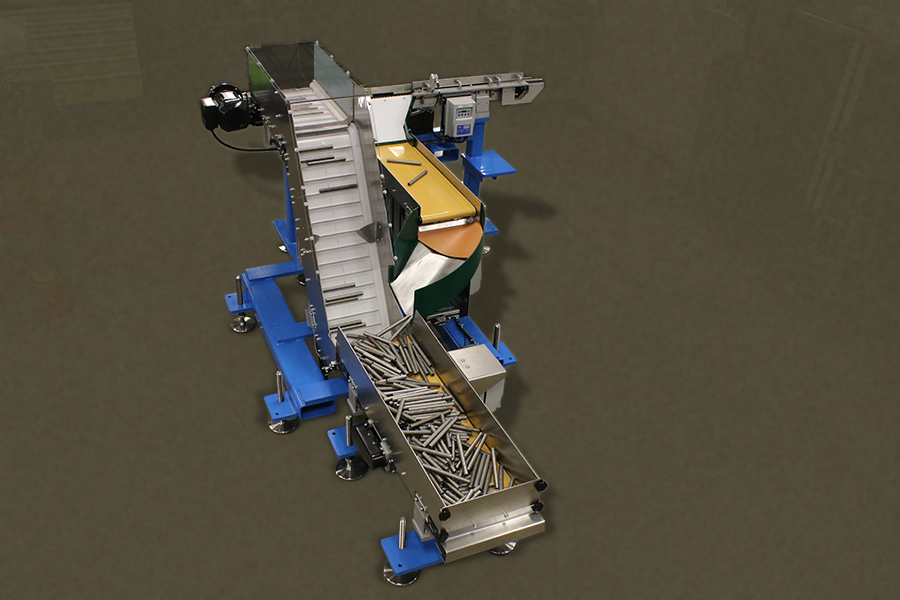

Problem: A manufacturer of storage and shipping tubes was looking for a parts-feeding system that would work with their metal stamping unit. The parts needed to be both loaded and unloaded from the six-position stamping press every two seconds without misfeeding or...

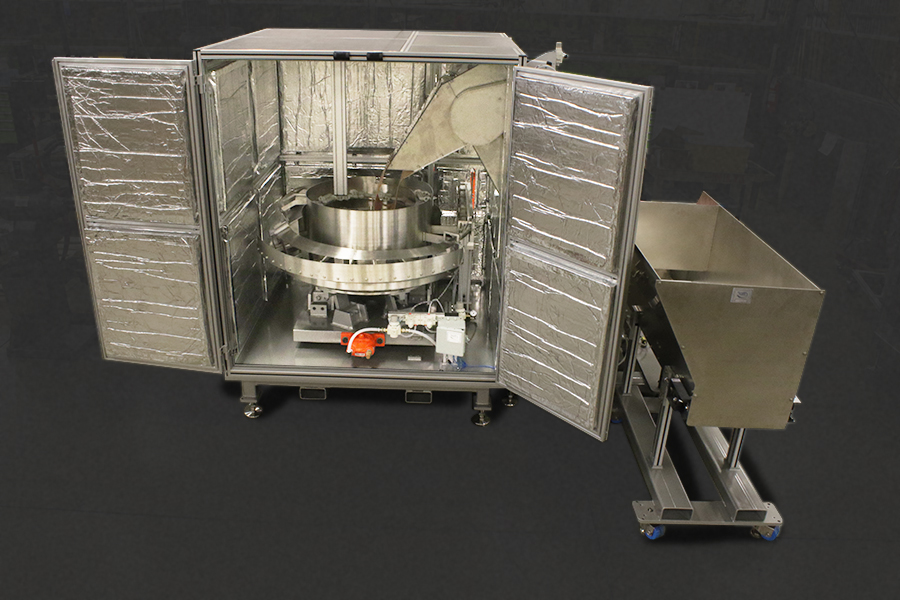

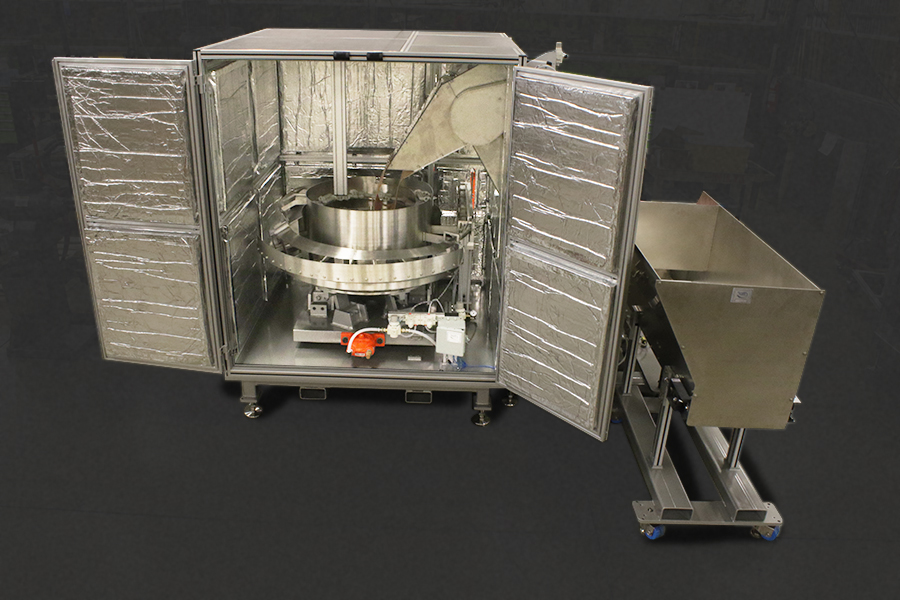

by Fortville Feeders | Sep 1, 2023 | Featured, Feeder Bowls

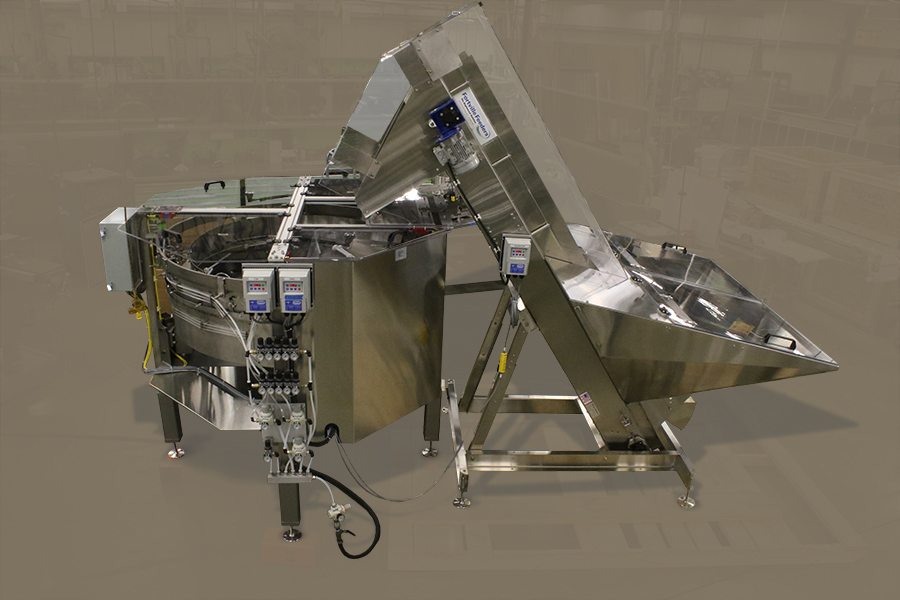

Problem: A manufacturer of syringe filling machines needed a complex parts feeding system. They were designing a system for operations in a C1D1 manufacturing environment where highly flammable and explosive material was being used. That required no electrical wiring...

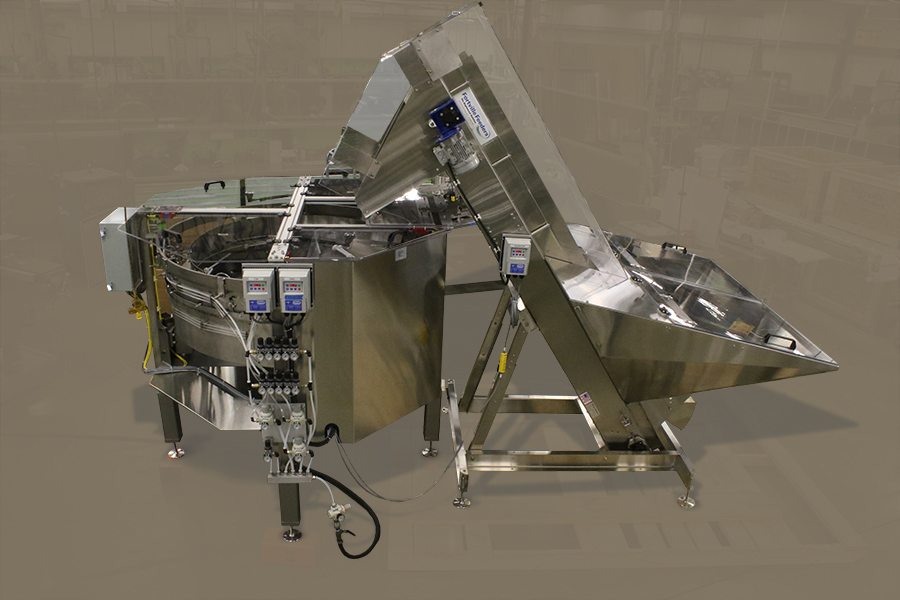

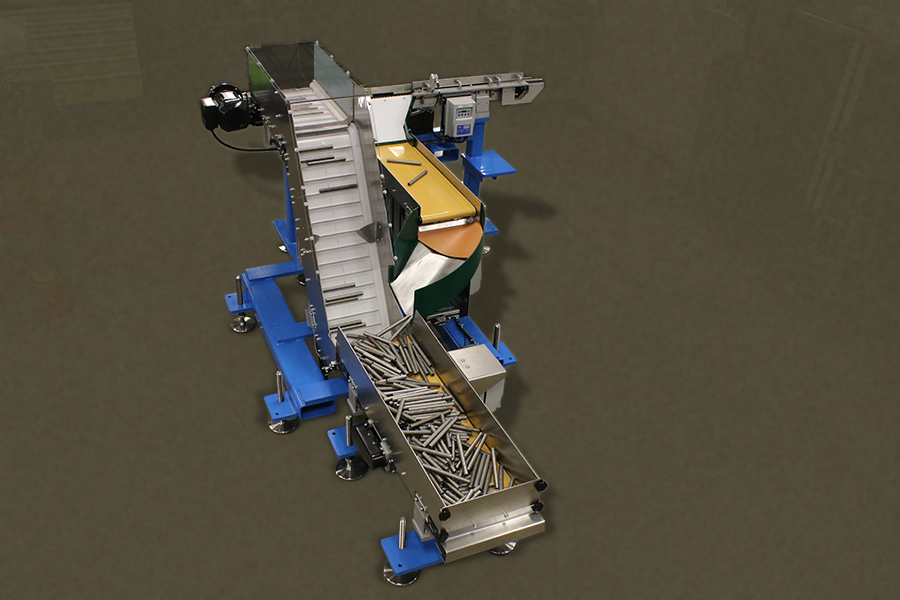

by Fortville Feeders | Jun 22, 2023 | Featured, Tracking Systems

Problem: The manufacturer of auto parts was looking for a new parts feeder solution for an assembly cell. Their engineers had designed the assembly cell with a dead nest to handle four parts, which were assembled and placed on a conveyor. This required the parts to be...

by Kevin Yaney | May 4, 2023 | Uncategorized

Problem: An integrator was in need of a high-speed parts feeder for a plastic pump and cap for a bottling assembly station. The customer had used a centrifugal feeder in the past and desired to have a duplicate machine built. In this case, the customer needed a system...

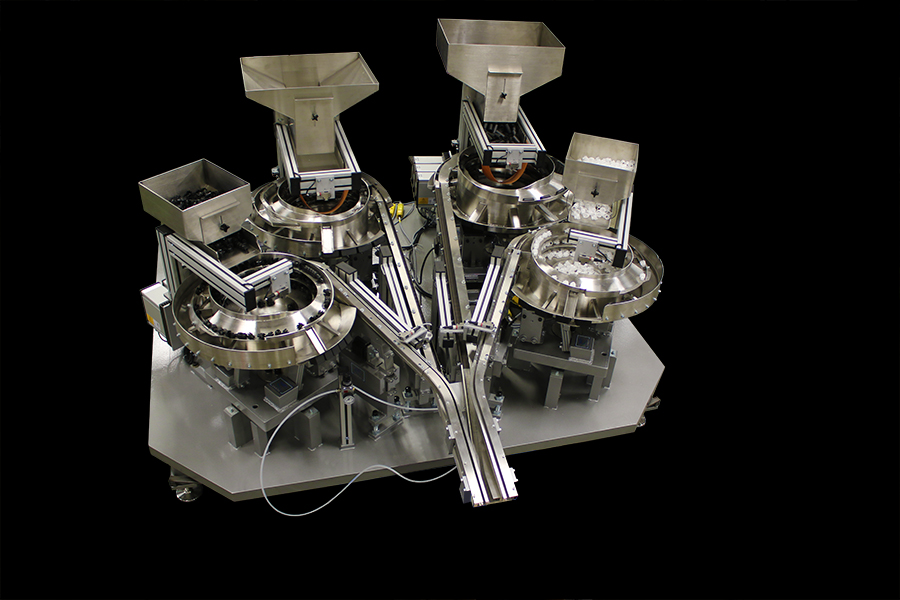

by Fortville Feeders | Dec 20, 2022 | Featured, Hoppers

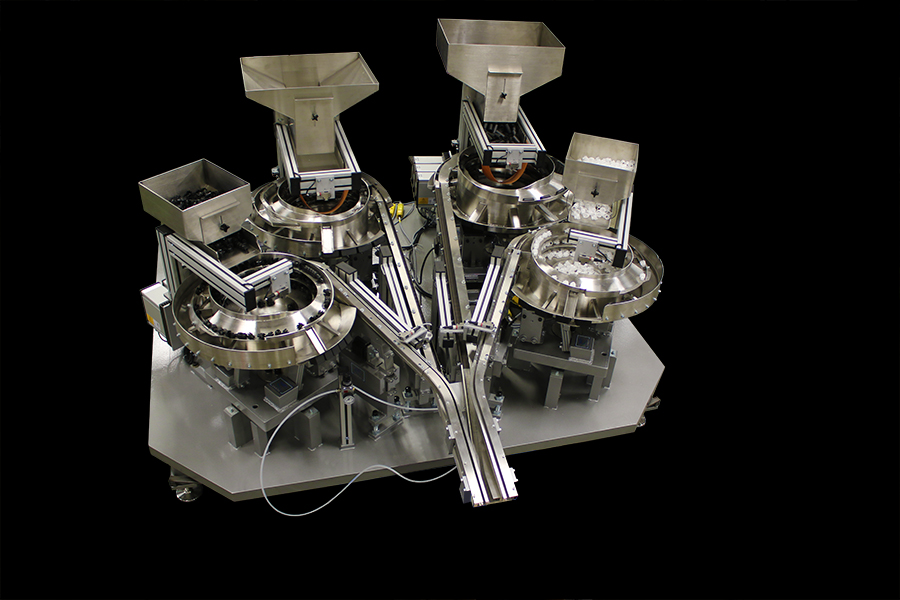

Problem: An integrator was building an assembly station that used four different parts in a hydraulic fabrication. They were looking for a parts feeder that could feed all four parts to an assembly cell. However, there were some unusual safety constraints. For safety...

Recent Comments