by Fortville Feeders | Jun 11, 2020 | Escapements and Mechanisms, Featured

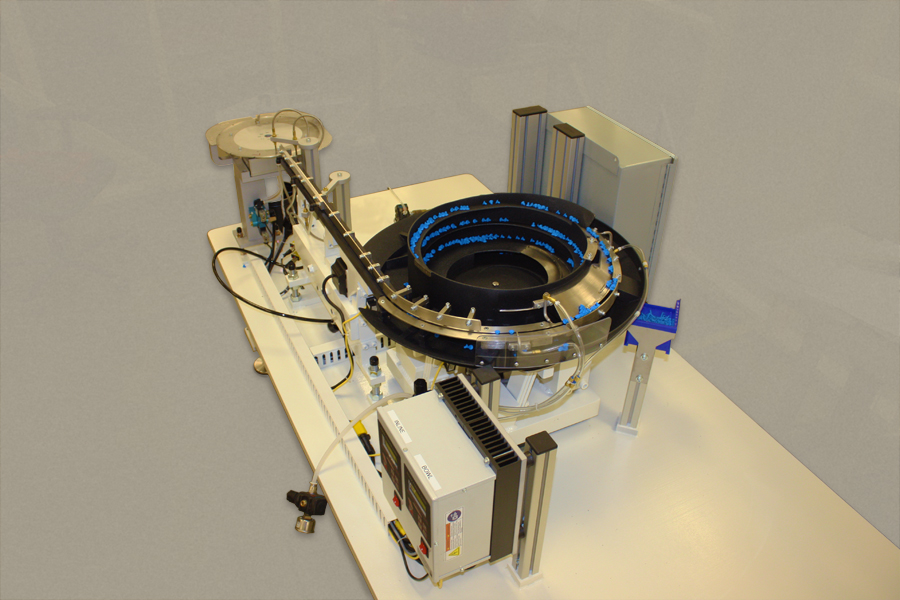

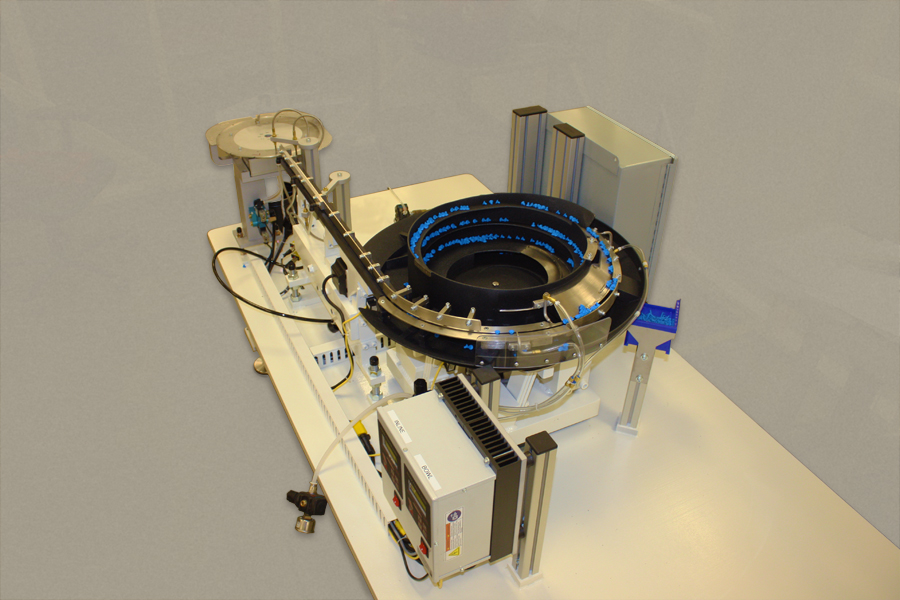

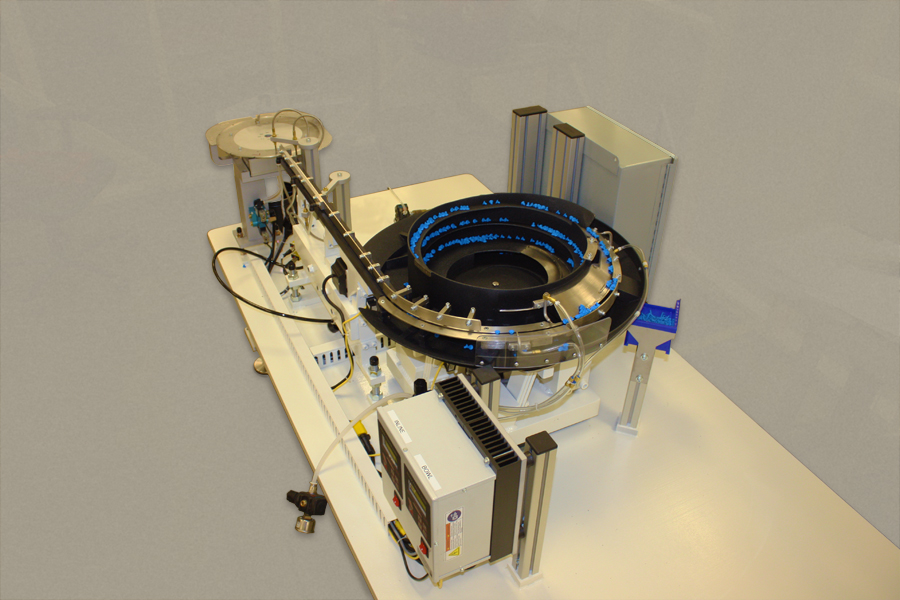

A manufacturer of valves needed an automated part feeding solution for a rubber insert that was a component of the product assembly. Fortville Feeders designed a vibratory inline feeder that fed a rotary actuator. The wheel handed parts off to the customer’s pick and...

by Fortville Feeders | Mar 12, 2020 | Tracking Systems

Problem: An integrator was building a parts resonance testing machine that checked powdered metal parts for defects. Powdered or sintered metal is prone to inclusions – cracks or pockets where air is trapped which weakens the structural integrity of the part....

by Kevin Yaney | Nov 22, 2019 | Escapements and Mechanisms

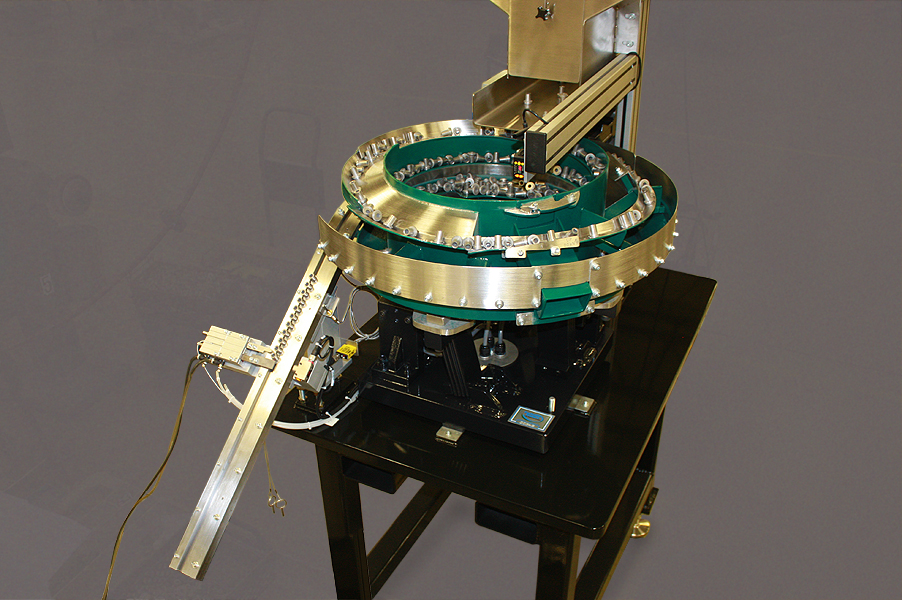

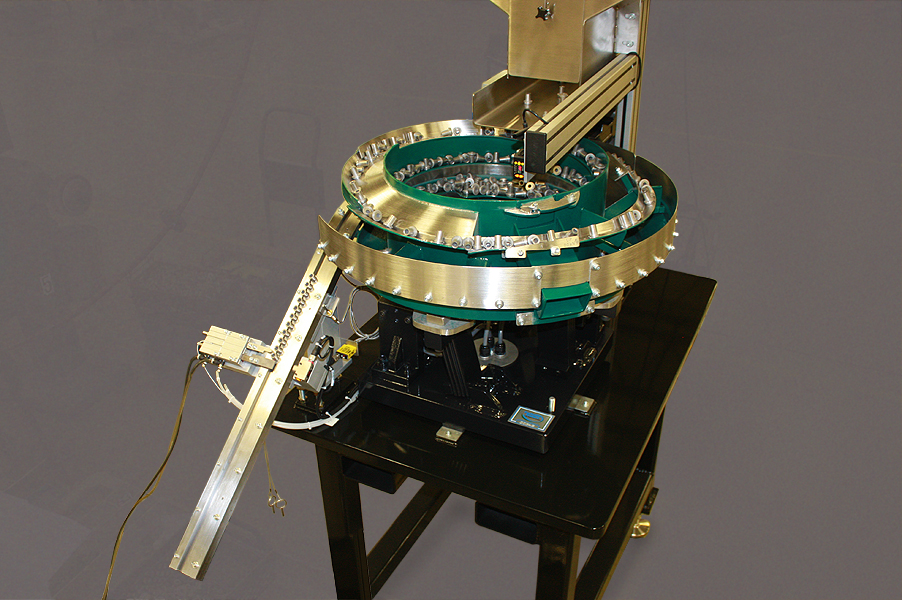

Problem: A lawnmower manufacturer needed to update a parts feeder on their assembly line. The equipment fed two components of a magneto to a robot. The two parts needed to be assembled, with a magnet placed inside a plastic holder before the robot picked it up....

by Kevin Yaney | Nov 5, 2019 | Feeder Bowls, Tracking Systems

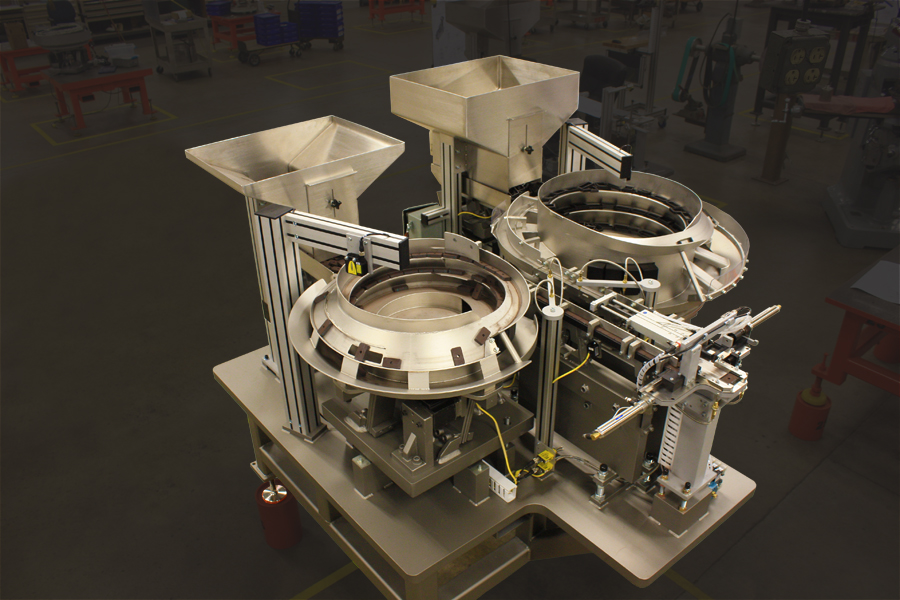

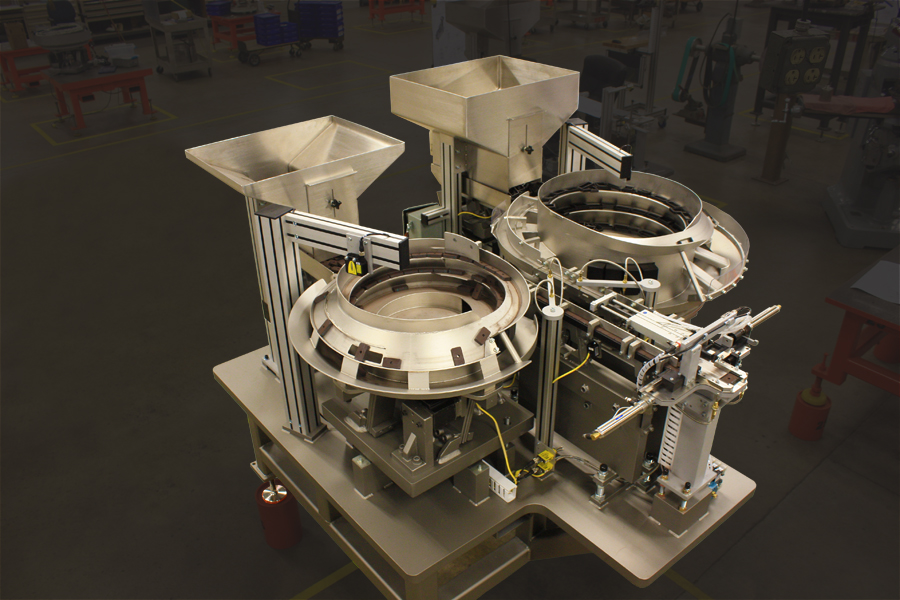

Problem: The manufacturer of water treatment control valves was looking for a way to automate their parts feeding and loading system that would continuously feed five conveyors that supplied their assembly station. The loading had previously been done by hand. The...

by Kevin Yaney | Sep 24, 2019 | Tracking Systems

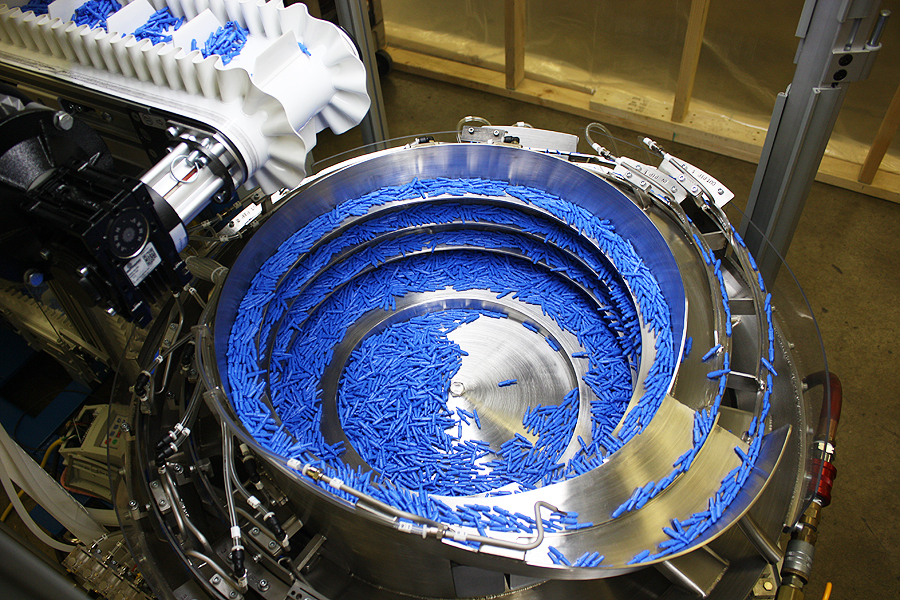

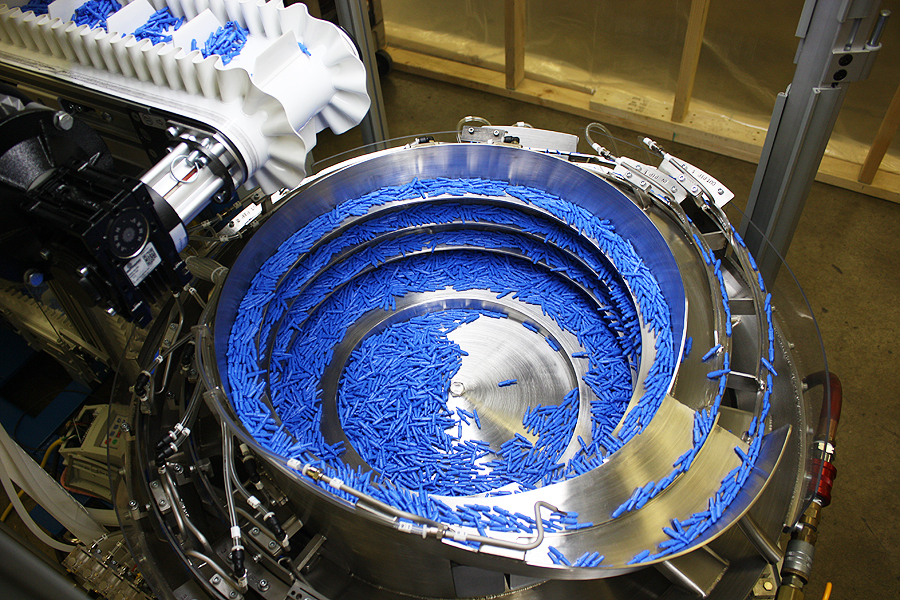

Problem: A manufacturer of ear protection devices needed two small parts – stems for earplugs – fed to their assembly equipment at a high rate of speed. The plastic stems had to be oriented properly, with the smaller diameter end leading. Any damaged or...

Recent Comments