by Fortville Feeders | Jun 26, 2019 | Feeder Bowls

Problem: International Engineering is a producer of snowmobile performance and safety traction products. They had been operating an aging automated parts feeder system that took an extensive amount of time to changeover from one part to another. IE had 13...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls

Problem: The customer was handling very small parts with a tapered end that needed to be sent down their assembly line standing up on the part’s base. The size of the part made it difficult to orient, select and contain particularly with a radial feeder...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls

Problem: The customer had an OEM feeding system that moved parts to the next operation with air. The parts needed to be oriented correctly for the next phase of their operations, but their system fed the parts in the opposite orientation. Their system had a...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls

Problem: The customer was working with two different sizes of braze beads that they wanted to sort and feed down an automated line. Solution: Fortville built a bulk hopper that fed the beads into a vibratory feeder bowl. This allowed the operator to...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls

Problem: The customer was dealing with very thin metal parts that would often misfeed in their automated system. They needed a way to supply the parts in an accumulative fashion (edge to edge) without overlapping. Solution: Fortville designed a vibratory...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls

Problem: The customer needed to present thin steel blades down an assembly line in a specific orientation. However, the parts were essentially symmetrical, with the exception of a small notch which needed to be presented on the right side. With no real...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls

Problem The customer needed a way to feed large bolts of varying lengths to its heavy duty wheel hub assembly cell. They manufacture eight different axle assemblies, each with a different size wheel bolt. They needed a feeder system that could handle all eight...

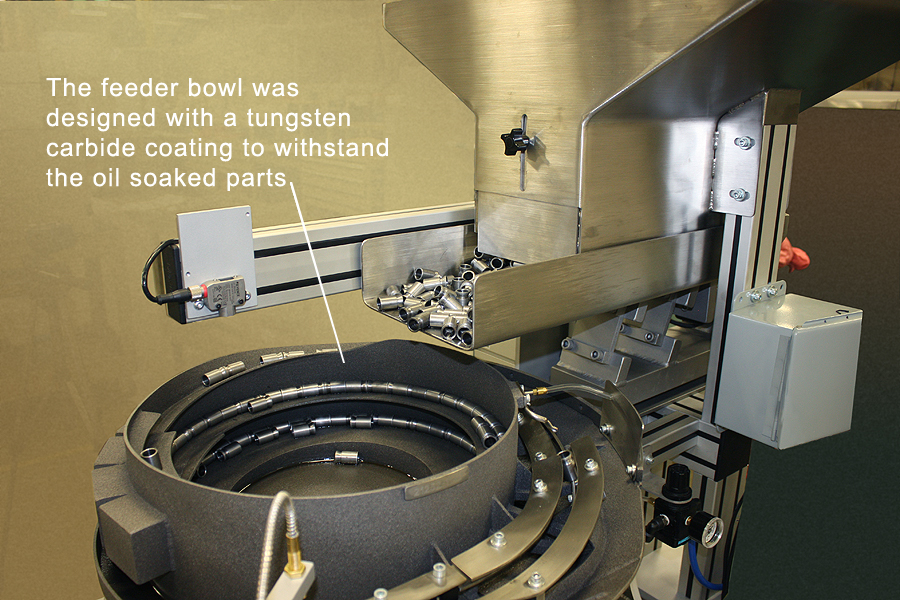

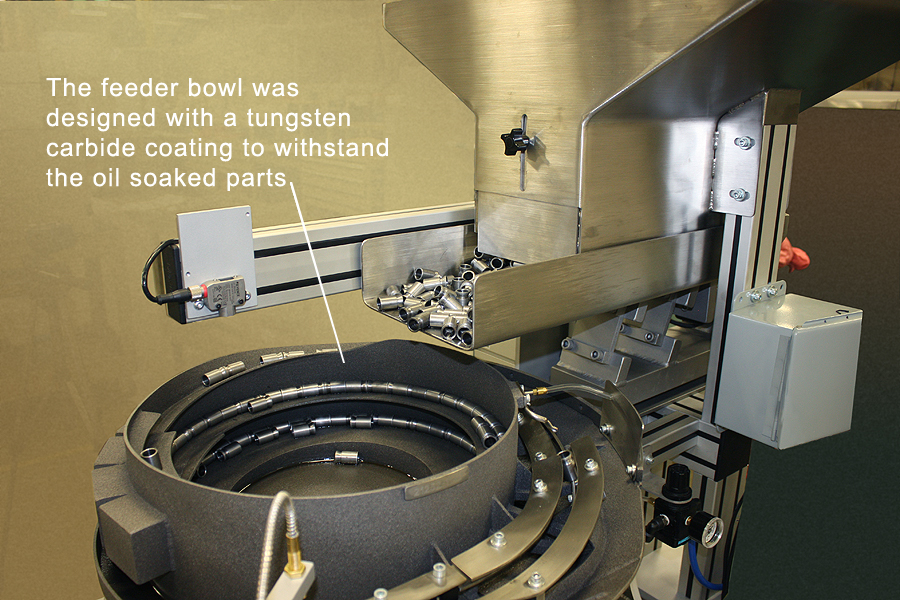

by Fortville Feeders | Jun 26, 2019 | Escapements and Mechanisms, Feeder Bowls

Problem: The customer needed to have a flux sleeve steel part oriented and isolated for robotic arm pick up. The problem: the parts were required to be drenched in oil prior to pick up. Oily parts are not only messy, they have a tendency to stick together or...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls

Problem: A manufacturer of toothbrushes had six different styles of toothbrushes, each with an ergonomic handle with soft rubber finger grips. They were looking for a feeder system that would sort, orient, and move the product to their laser etching and packaging...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls

Problem: The customer was an integrator who was looking to replace a feeder system for a three-part automation system. The parts were constructed of steel, but were all dissimilar in geometry. The old system used three separate feeder bowls. It was the desire of...

Recent Comments