by Fortville Feeders | Jul 22, 2024 | Uncategorized

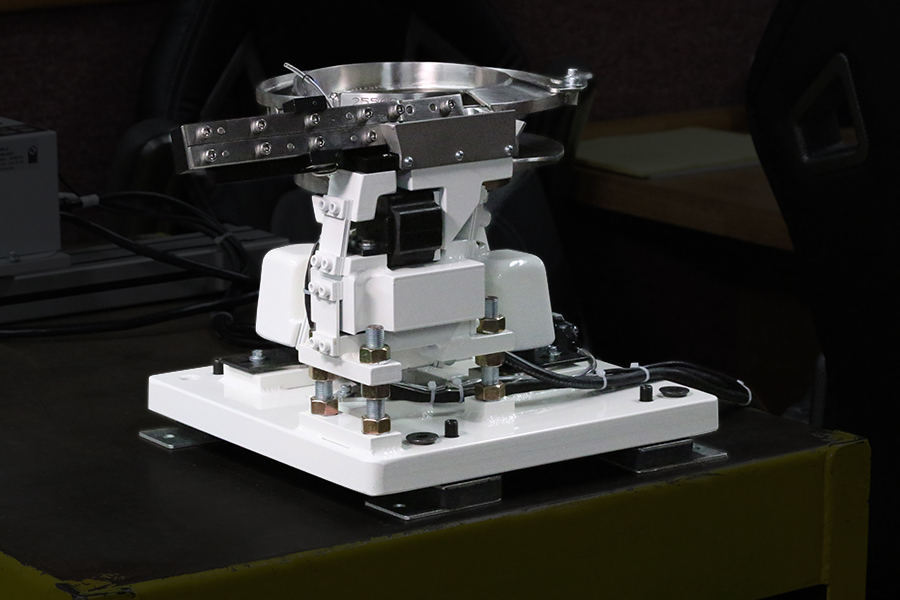

Problem: A medical parts manufacturer needed a parts feeder for the packaging of very small staples. Since this was a medical staple, the feeder system needed to meet cleanroom compliance standards. The part could not be handled during the feeding process and must be...

by Fortville Feeders | Jun 28, 2022 | Featured, Hoppers, Tracking Systems

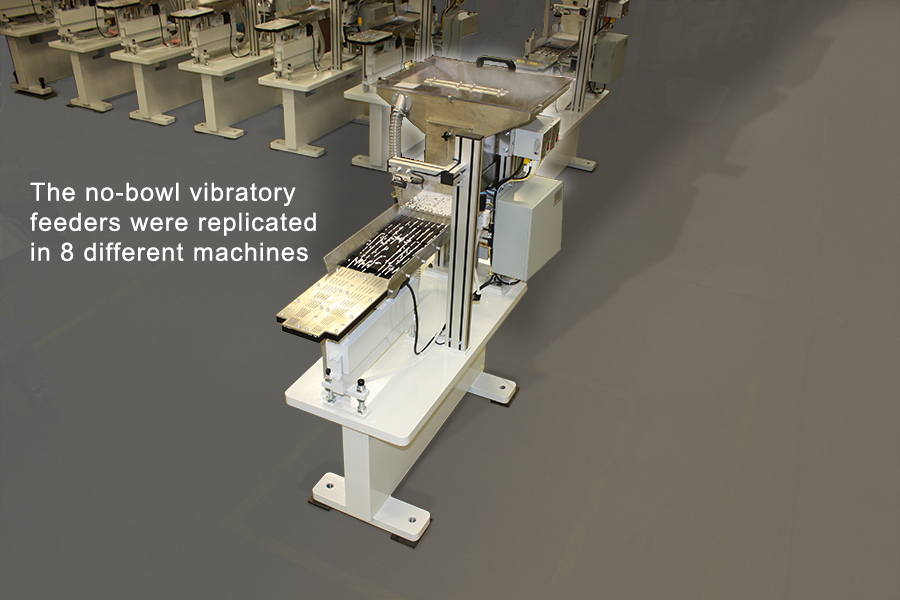

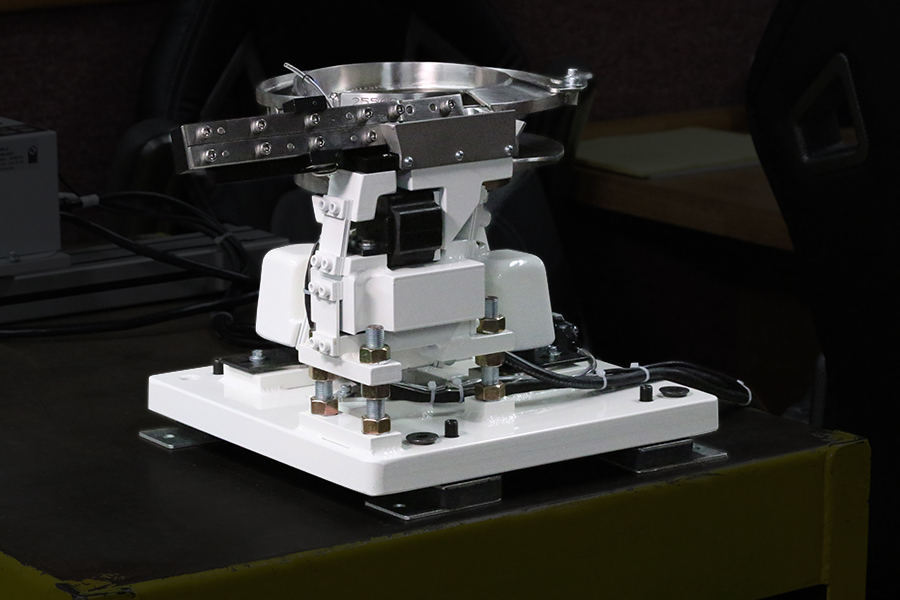

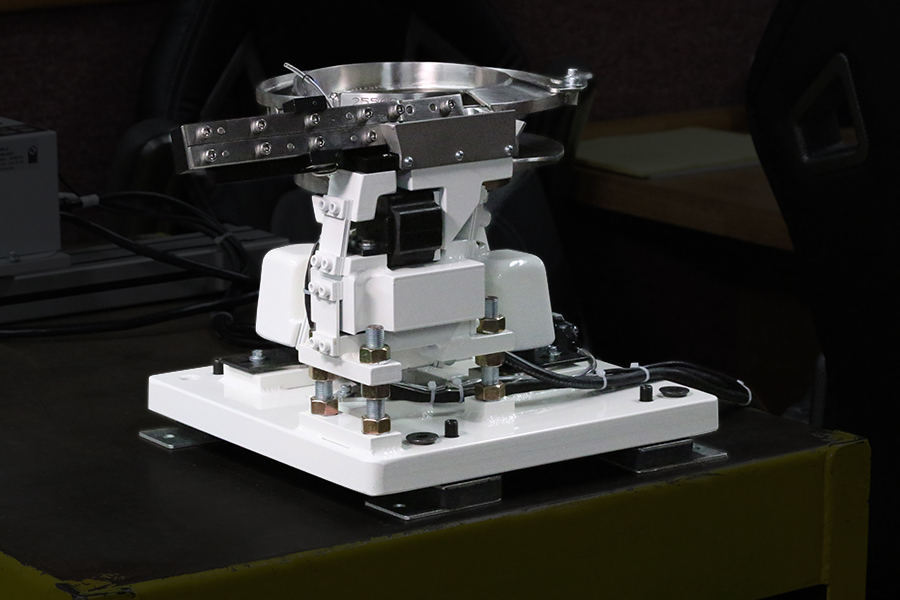

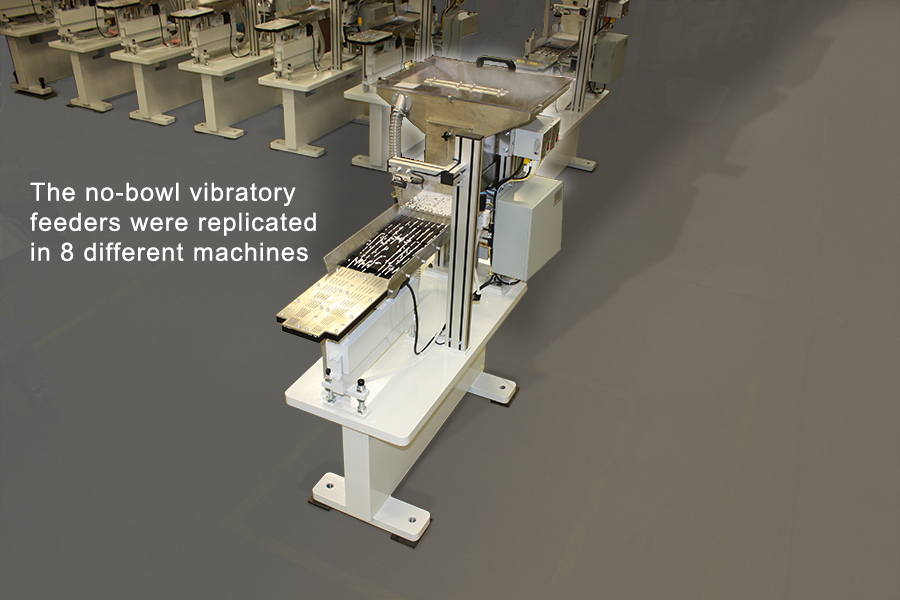

Problem: An integrator needed eight parts-feeding systems that would feed oblong plastic parts at high speeds. The only difference in the machines were the number of lines needed to feed the assembly line. They asked for a traditional vibratory feeder bowl system that...

by Fortville Feeders | May 24, 2022 | Escapements and Mechanisms, Featured

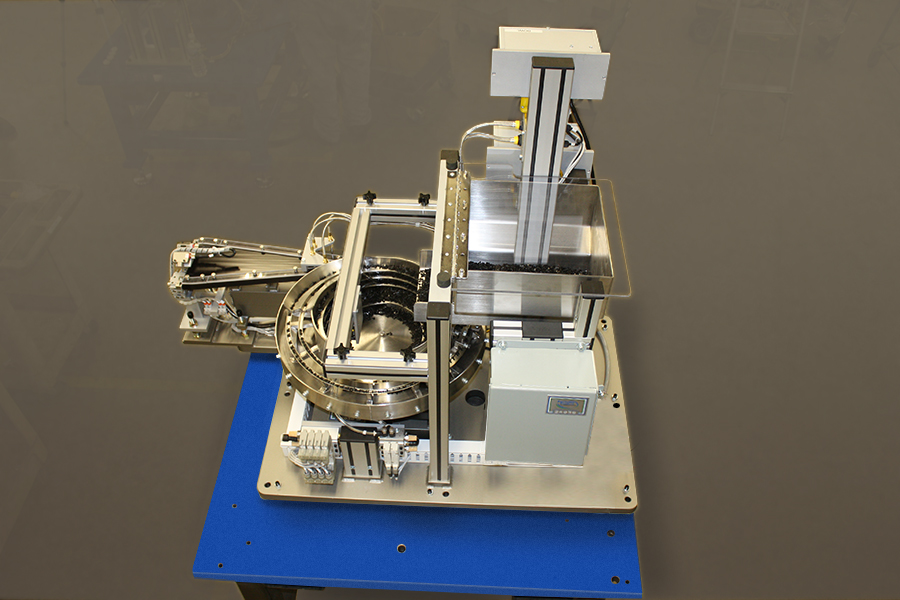

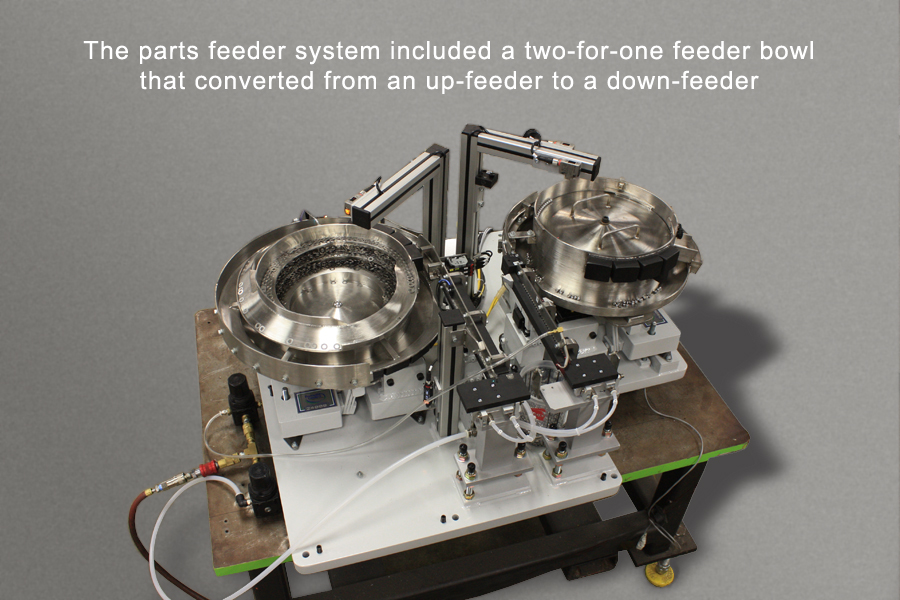

Problem: An integrator was looking for a way to feed tiny plunger parts. The parts had a flat, oblong head with a hole running through the length of the head. The parts needed to be presented to four pickup positions with the heads up and the holes facing forward. ...

by Fortville Feeders | Apr 16, 2022 | Escapements and Mechanisms, Featured, Tracking Systems

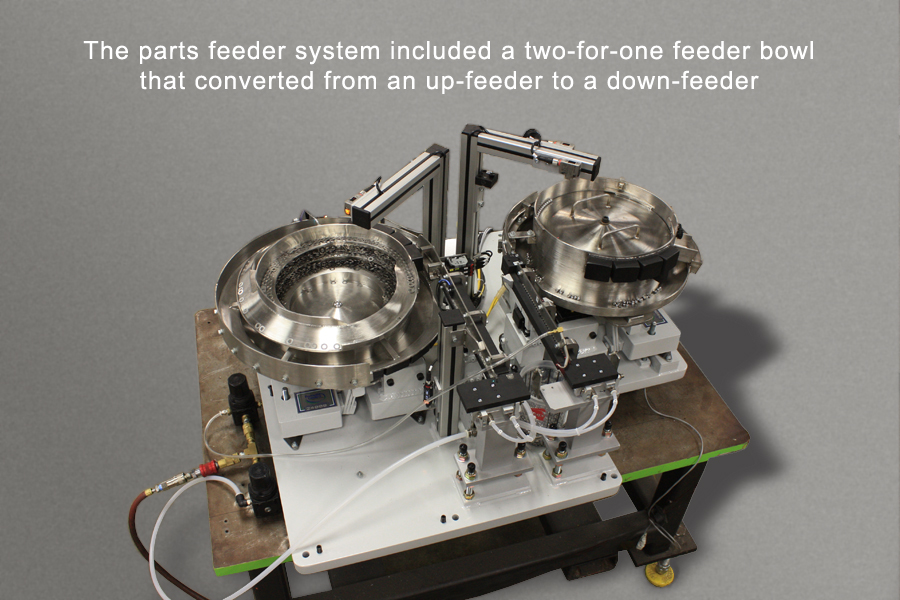

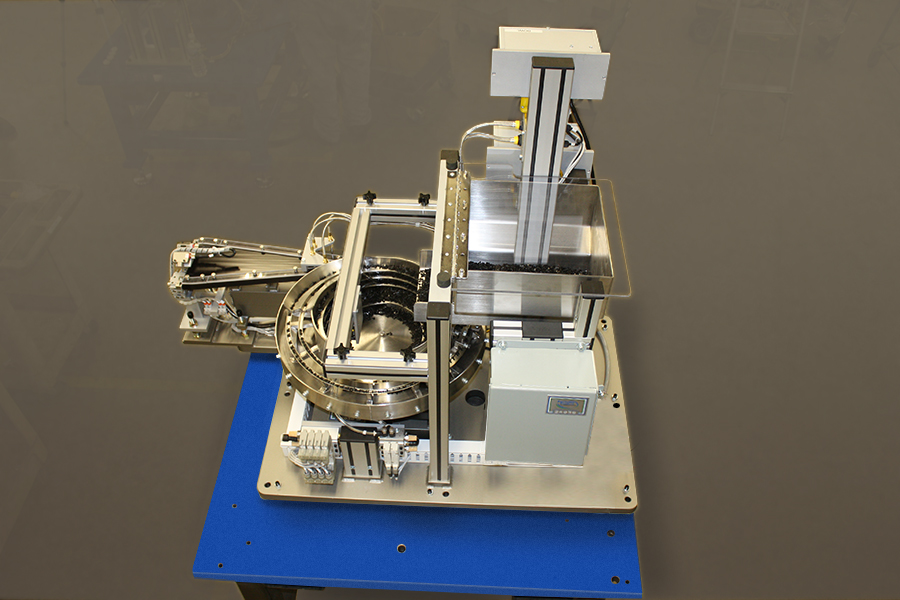

Problem: An integrator was looking for a new parts feeding system for their robot assembly of bearings. The client had two different bearing parts. One was fully round and the other was a half-round bearing. Both of these bearings were seated in a chamfered retainer...

by Fortville Feeders | Feb 12, 2020 | High Speed Feeder Bowls, Tracking Systems

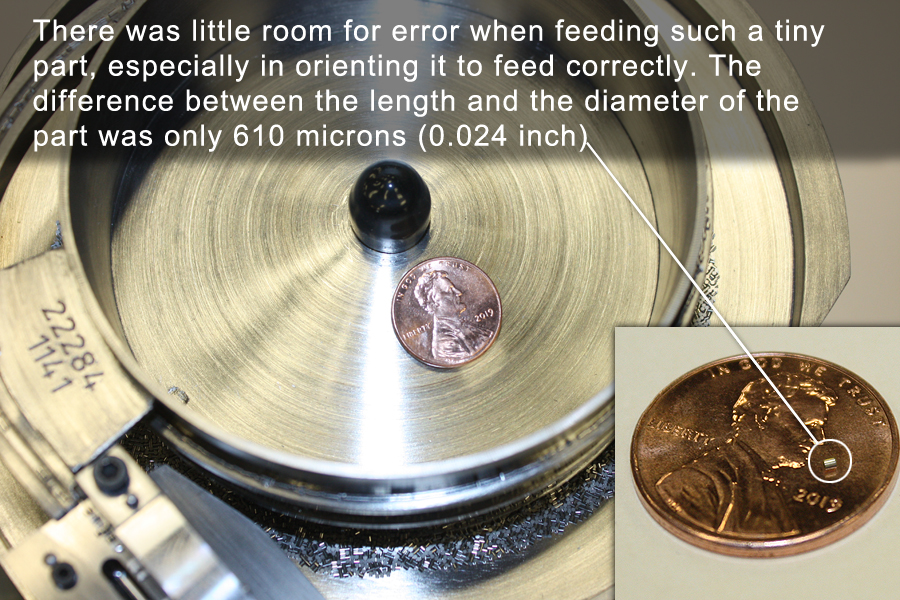

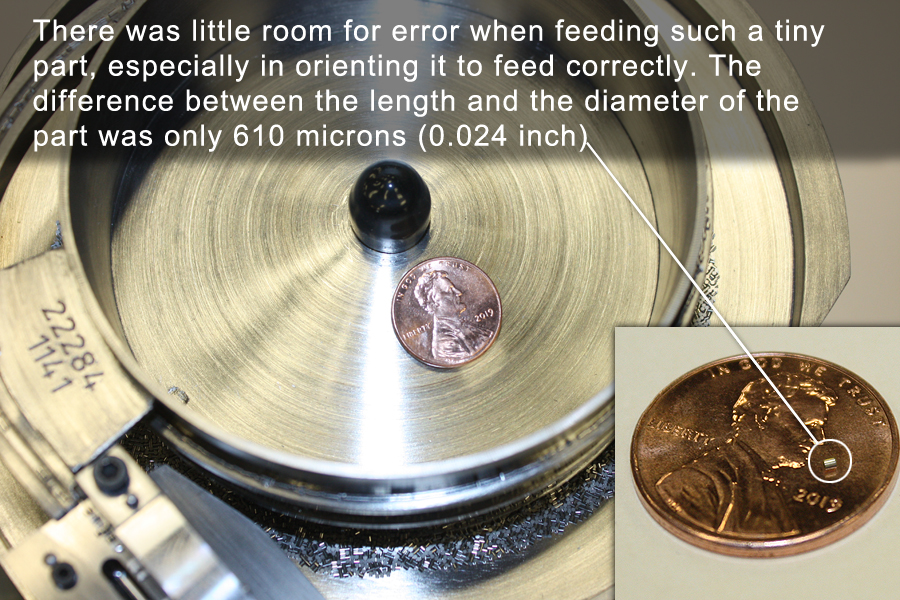

Problem: Fortville Feeders will service any feeder system, regardless of its manufacturer. On one such service call to the manufacturer of spark plugs, the customer was having trouble getting a very small iridium electrode to feed correctly. The electrodes were...

Recent Comments