by Kevin Yaney | Aug 25, 2020 | High Speed Feeder Bowls, Tracking Systems

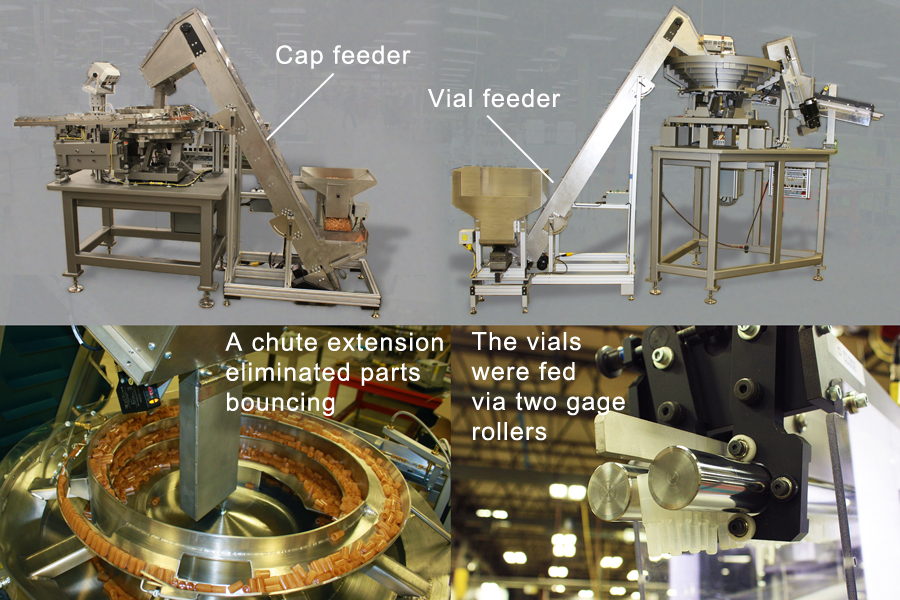

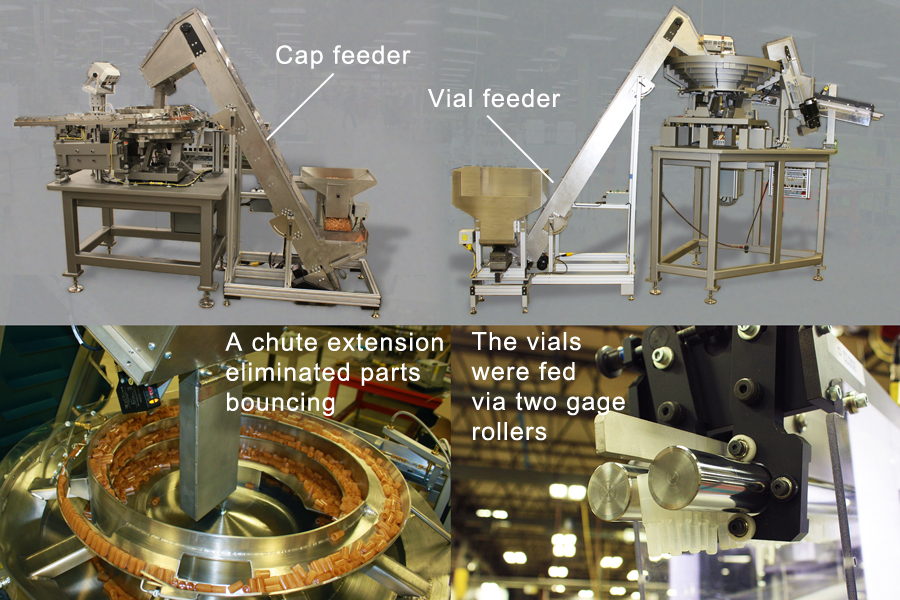

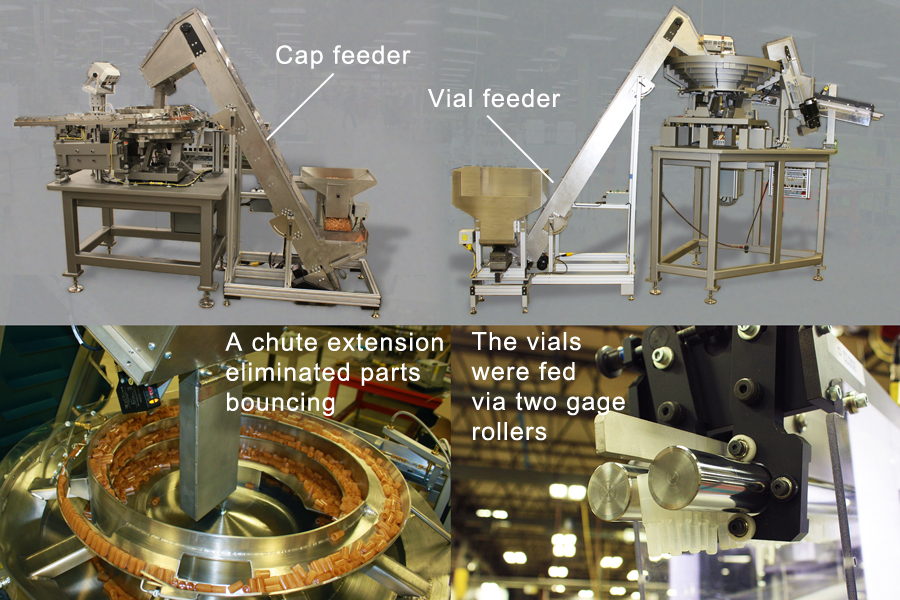

Problem: An integrator was building an assembly and labeling automation system for a medical packaging company. The high-speed system labeled vials and capped them before being filled. The customer needed two feeder systems; one for the vials and one for the caps,...

by Fortville Feeders | Jun 11, 2020 | Escapements and Mechanisms, Featured

A manufacturer of valves needed an automated part feeding solution for a rubber insert that was a component of the product assembly. Fortville Feeders designed a vibratory inline feeder that fed a rotary actuator. The wheel handed parts off to the customer’s pick and...

by Kevin Yaney | Apr 23, 2020 | Uncategorized

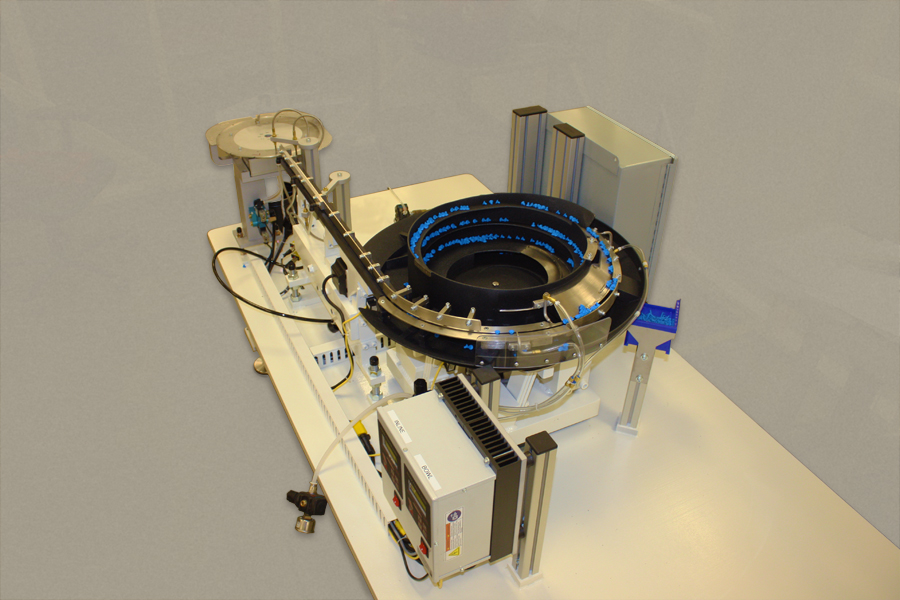

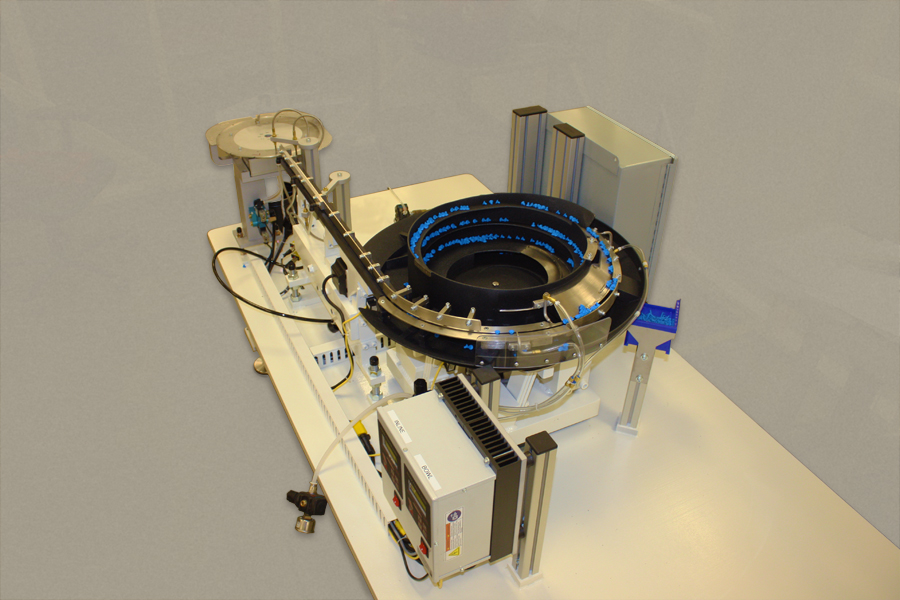

Introduction: An integrator located in Montreal, Canada needed a manufacturer to both produce and provide service on vibratory feeder systems. Even though the integrator typically does all of their own parts feeding systems on the automated machinery they produce,...

by Kevin Yaney | Feb 25, 2020 | Escapements and Mechanisms, Featured

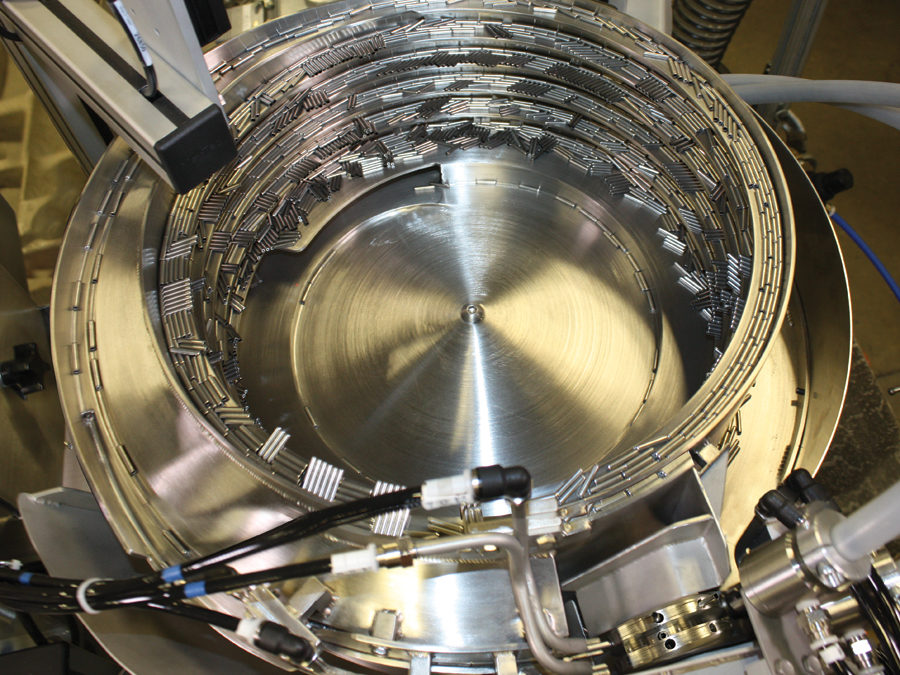

Problem: The manufacturer of critical control products was looking for a way to feed bulk pins to an assembly robot. The pins were small and, other than large and small openings at opposite ends, had no other distinguishing features. It was critical that the pins be...

by Fortville Feeders | Feb 12, 2020 | High Speed Feeder Bowls, Tracking Systems

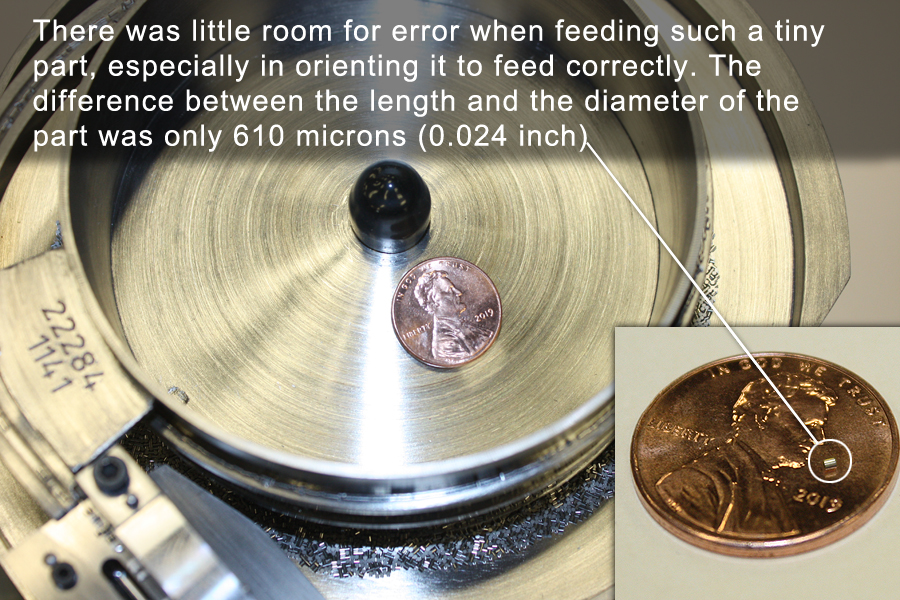

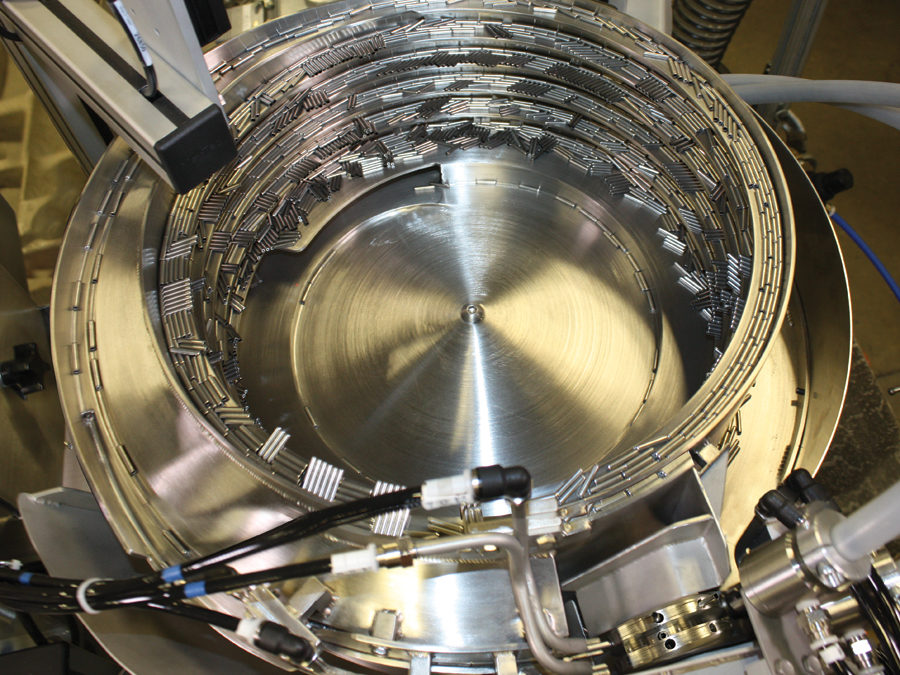

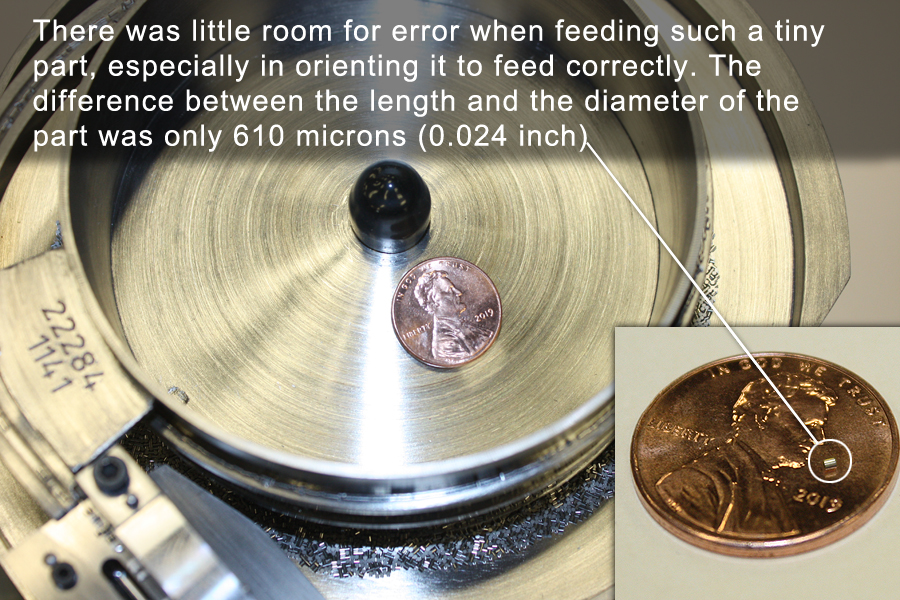

Problem: Fortville Feeders will service any feeder system, regardless of its manufacturer. On one such service call to the manufacturer of spark plugs, the customer was having trouble getting a very small iridium electrode to feed correctly. The electrodes were...

Recent Comments