by Fortville Feeders | Aug 15, 2022 | Featured, Feeder Bowls

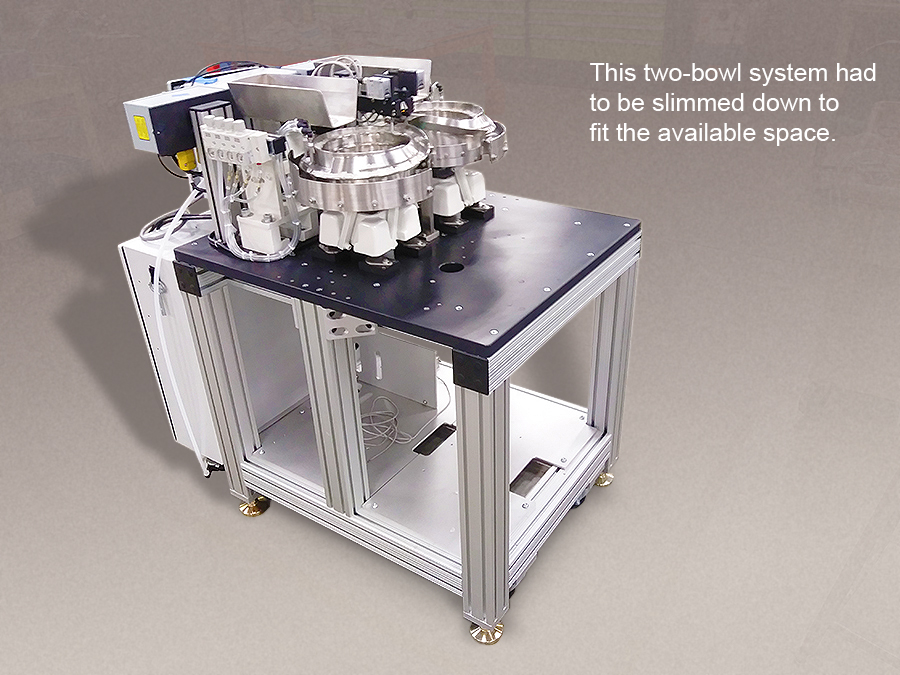

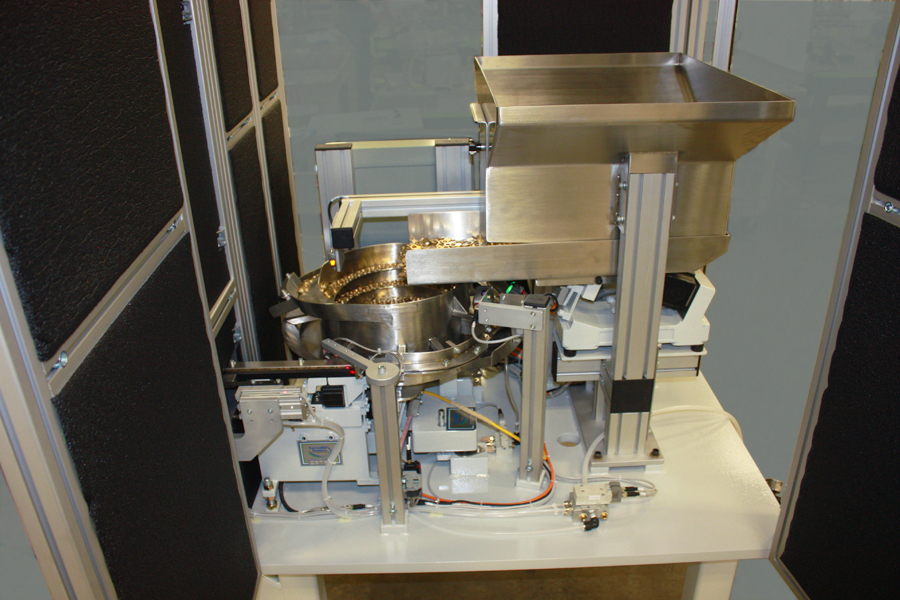

Problem: An integrator was building an assembly system that handled 64 different flat rubber seals. There were very tight quarters for the machinery, especially the feeder system. The space was so tight that the standard-sized feeder equipment would have to be sized...

by Fortville Feeders | Jun 28, 2022 | Featured, Hoppers, Tracking Systems

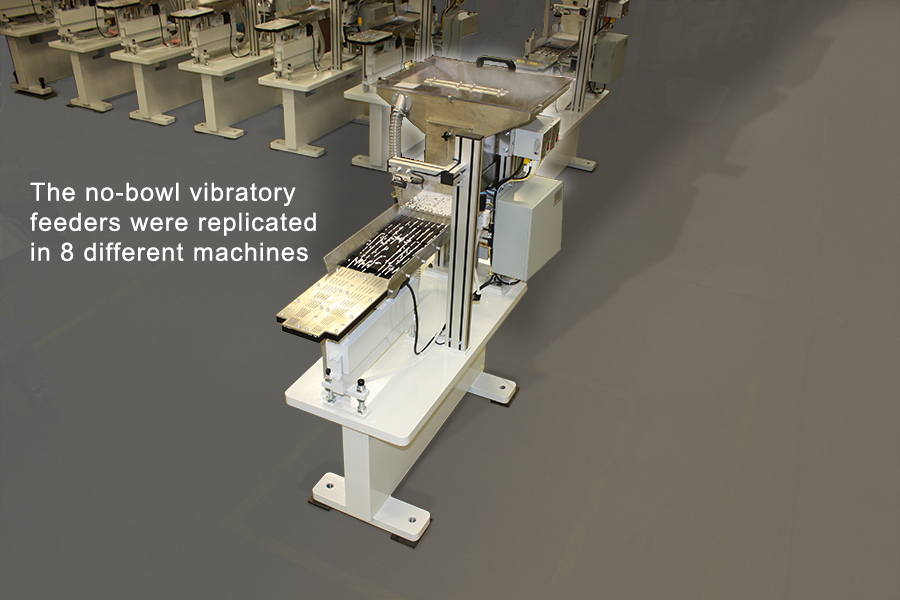

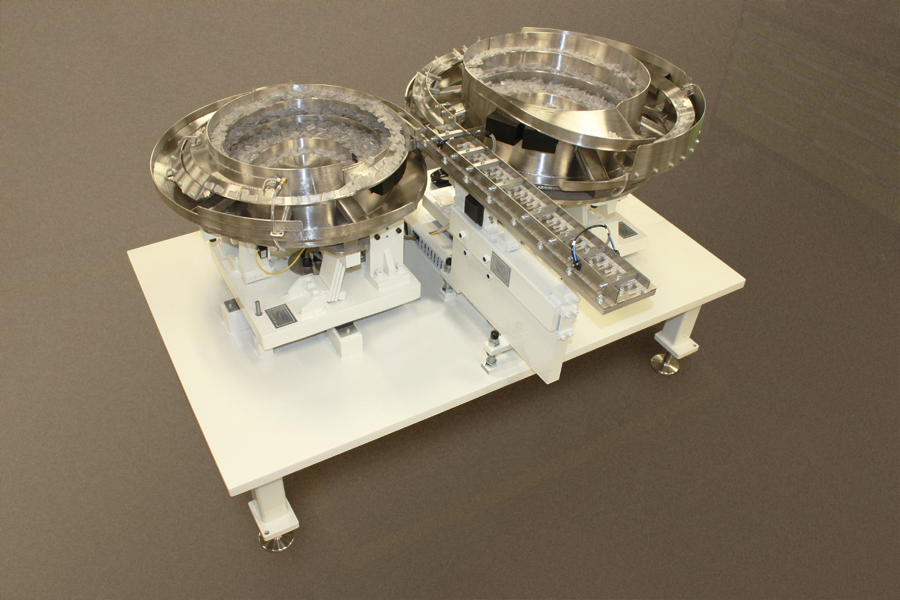

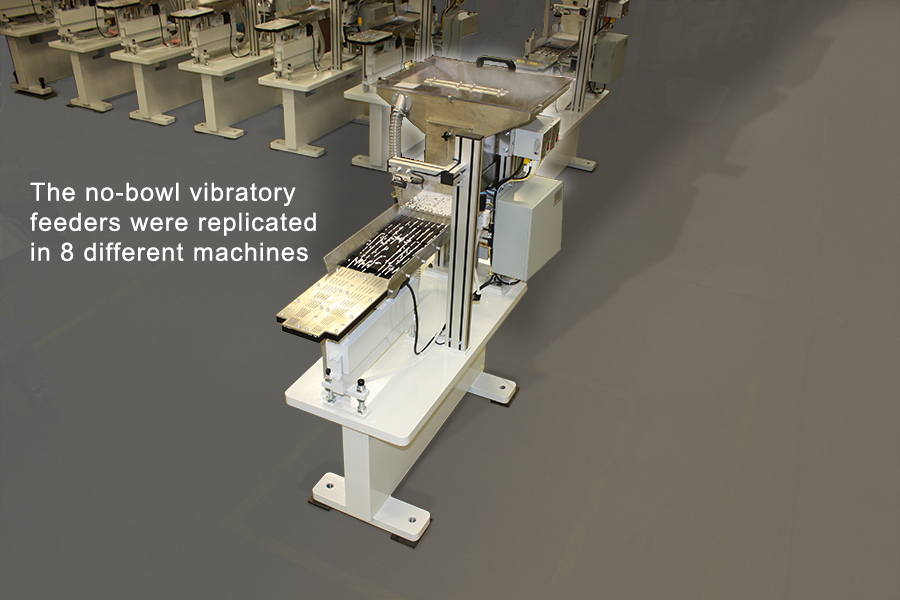

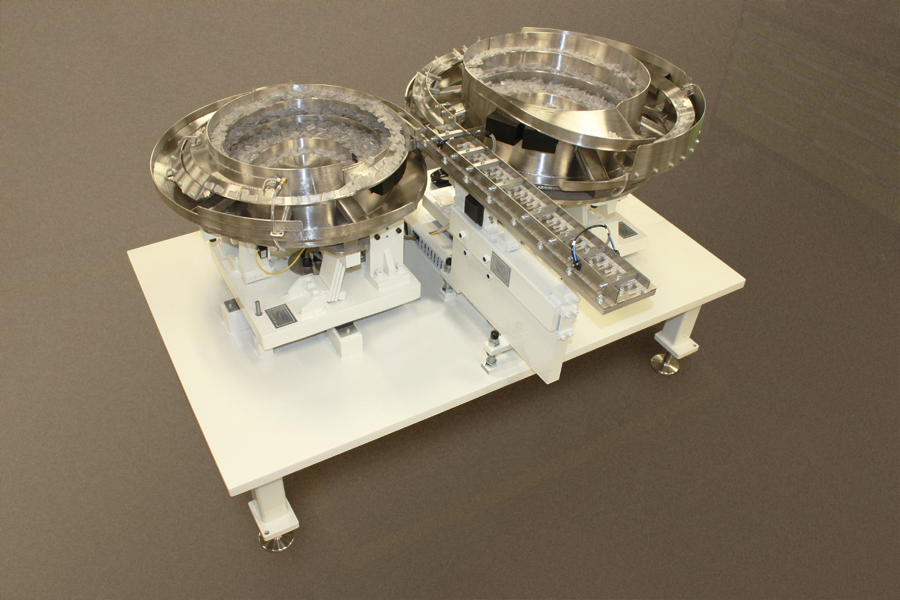

Problem: An integrator needed eight parts-feeding systems that would feed oblong plastic parts at high speeds. The only difference in the machines were the number of lines needed to feed the assembly line. They asked for a traditional vibratory feeder bowl system that...

by Fortville Feeders | May 24, 2022 | Escapements and Mechanisms, Featured

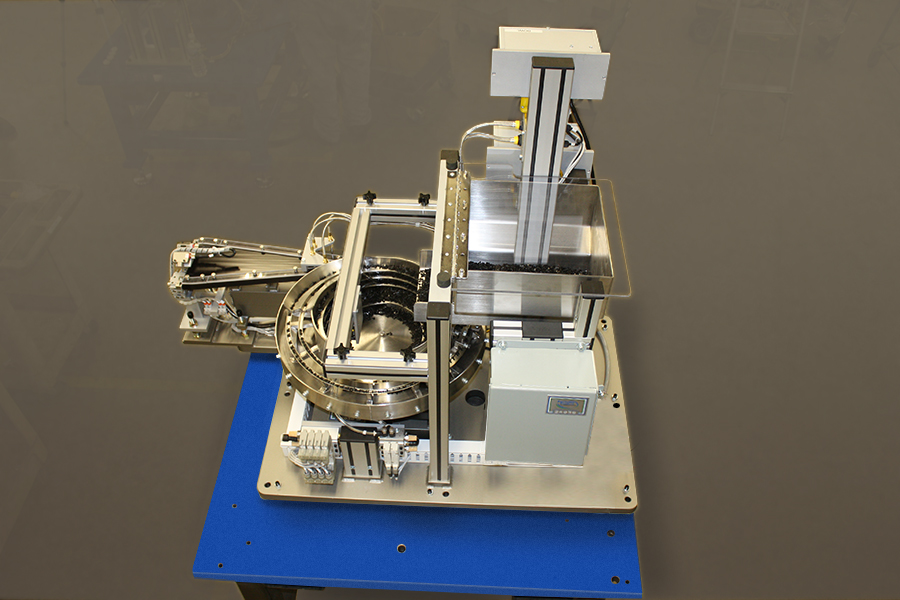

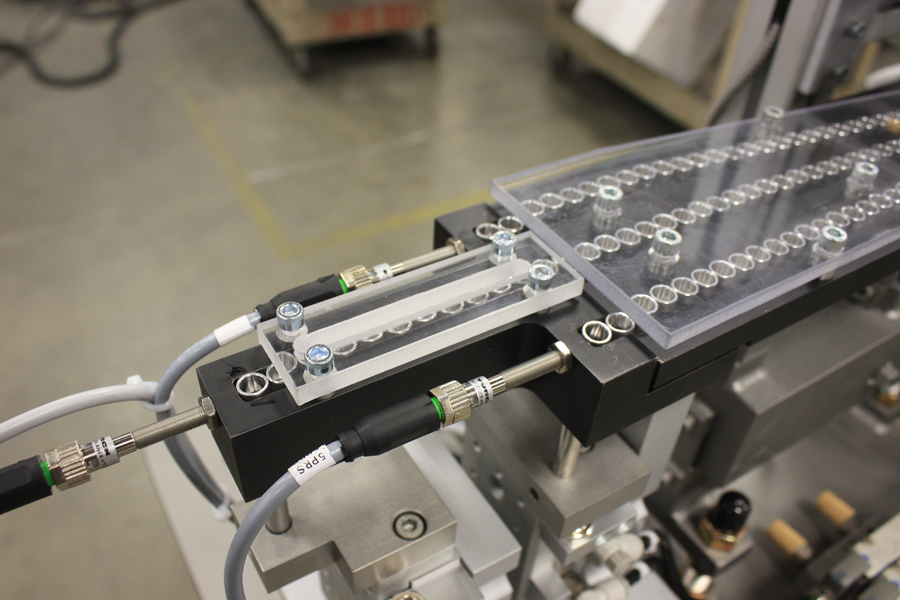

Problem: An integrator was looking for a way to feed tiny plunger parts. The parts had a flat, oblong head with a hole running through the length of the head. The parts needed to be presented to four pickup positions with the heads up and the holes facing forward. ...

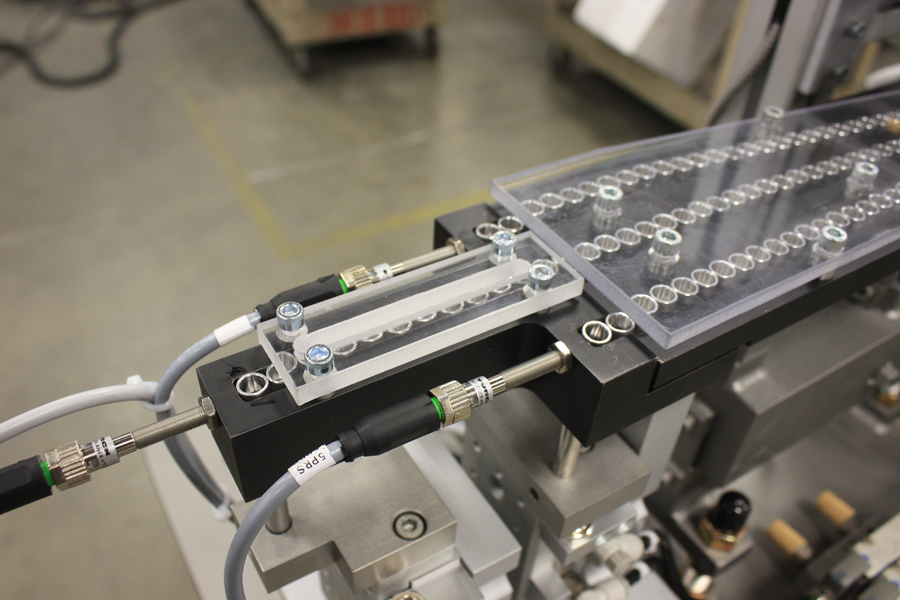

by Fortville Feeders | Apr 16, 2022 | Escapements and Mechanisms, Featured, Tracking Systems

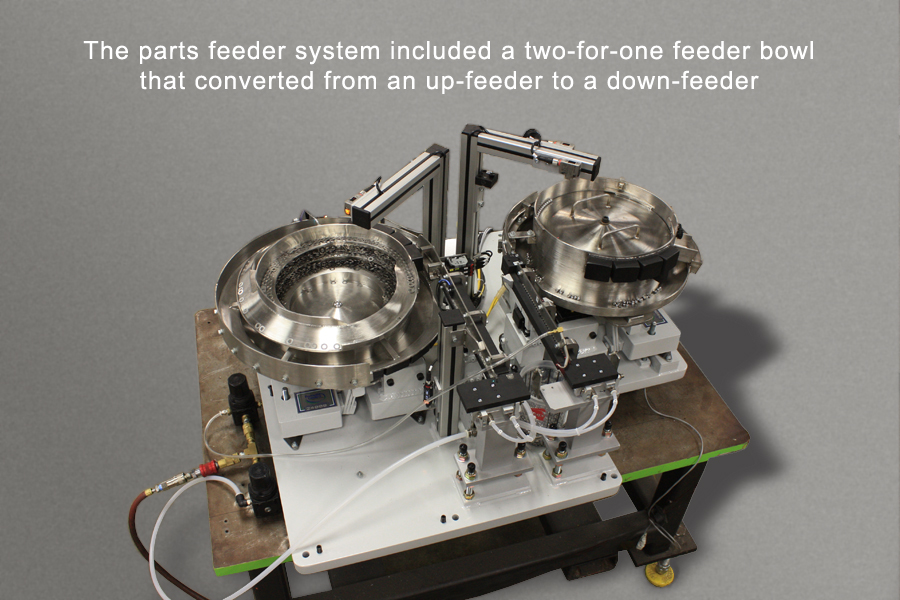

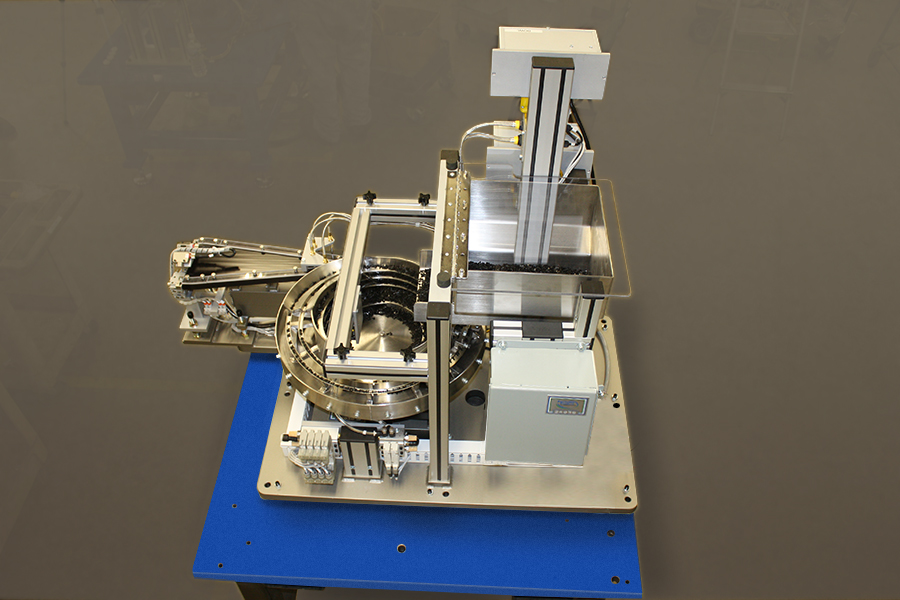

Problem: An integrator was looking for a new parts feeding system for their robot assembly of bearings. The client had two different bearing parts. One was fully round and the other was a half-round bearing. Both of these bearings were seated in a chamfered retainer...

by Fortville Feeders | Mar 22, 2022 | Featured, Hoppers

Problem: An integrator was looking for a solution to a parts handling issue. Large steel pipes were moved in a metal tub via a forklift to a loading station. They were looking for a way to safely load the heavy parts into a new vibratory parts feeder without tipping...

by Fortville Feeders | Feb 19, 2022 | Featured, High Speed Feeder Bowls

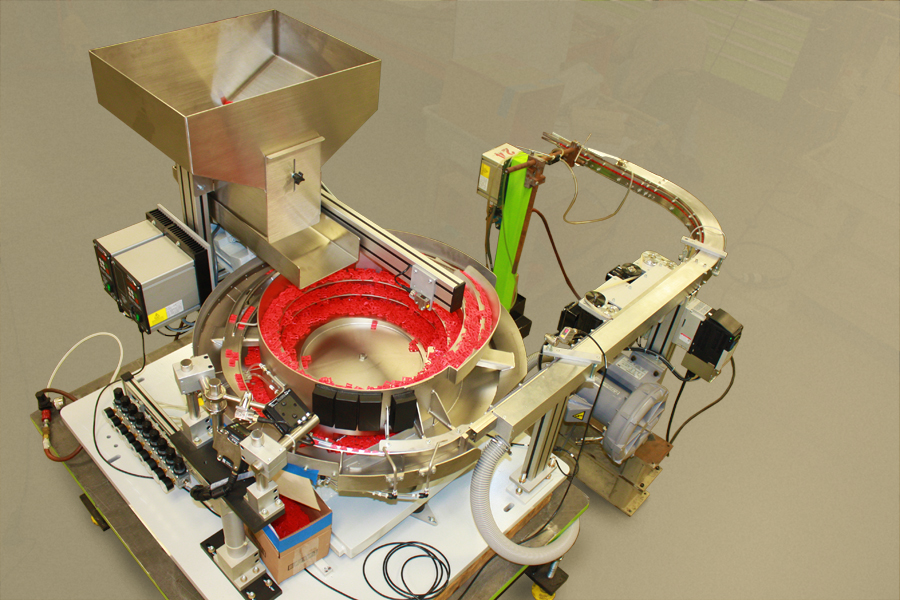

Problem: A manufacturer of metal components produces a conical spring and needed a feeder system that would handle bulk springs and deliver them at 140 parts per minute to their assembly station. The problem was the springs were easily tangled in bulk situations. The...

by Fortville Feeders | Dec 10, 2021 | Escapements and Mechanisms, Featured

Problem: The manufacturer of door hardware was in need of a way to automate the orientation and feeding of three different brass lock components for an assembly cell. The parts all shared the same two-lobe shape with one lobe having a hole and one being solid. Two of...

by Fortville Feeders | Oct 14, 2021 | Featured, Tracking Systems, Uncategorized

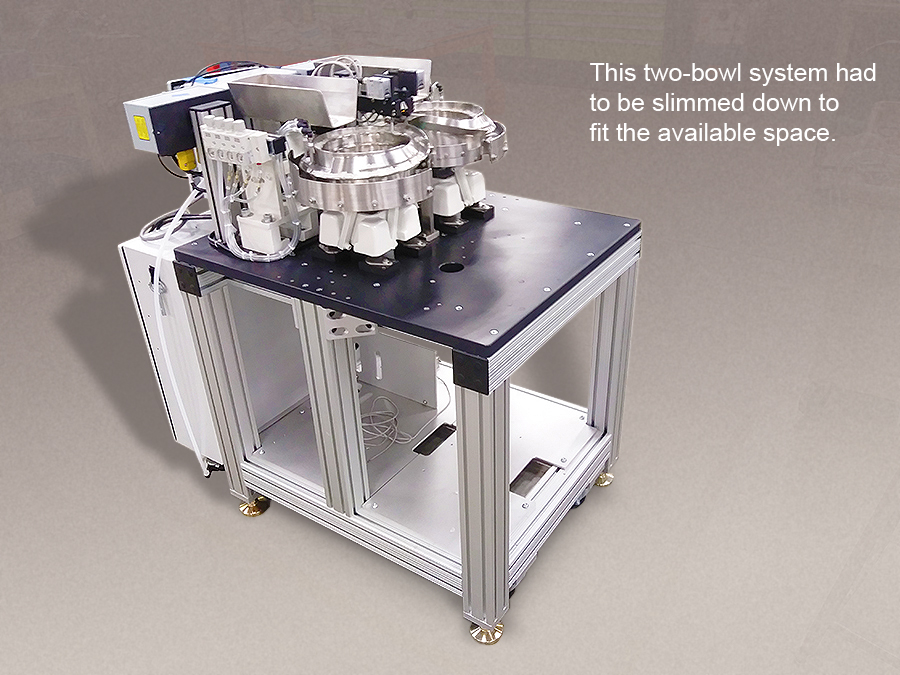

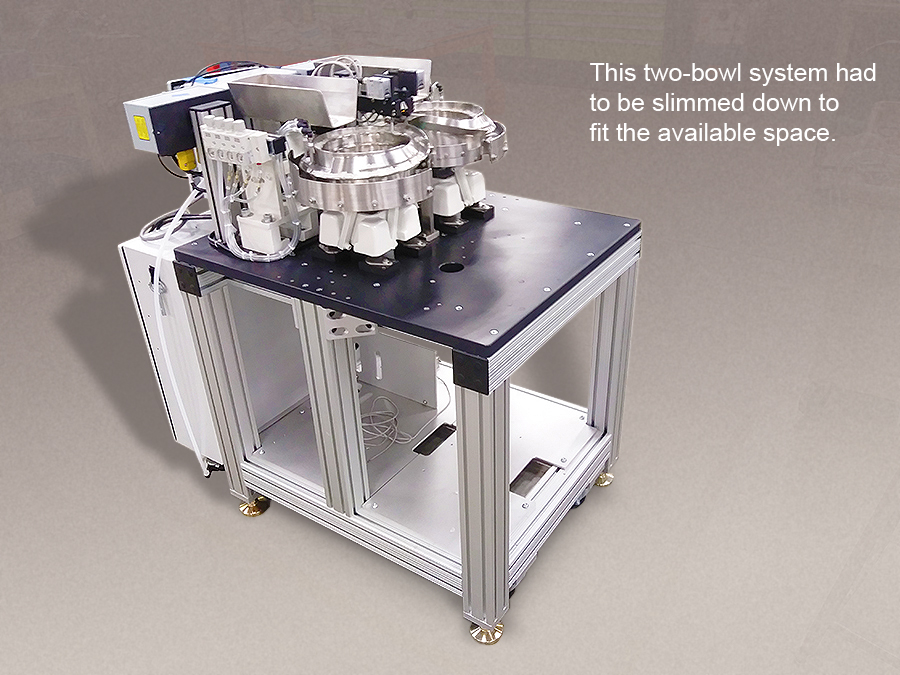

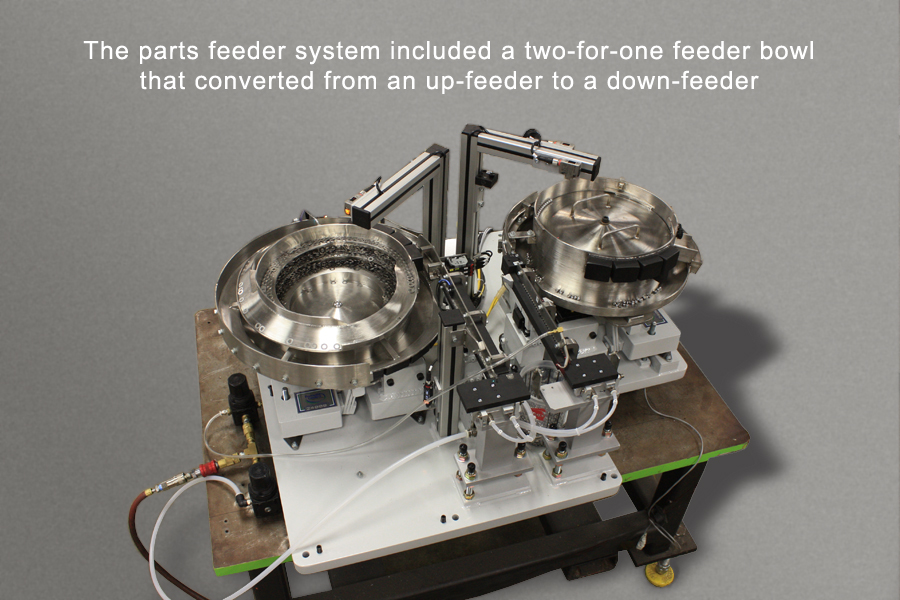

Problem: A medical device manufacturer needed to replace an inefficient feeder system for two caps. The system they had attempted to feed two parts from the same vibratory bowl. The two caps had very different geometries. It caused constant jams in their old feeder....

by Fortville Feeders | Aug 2, 2021 | Featured, Tracking Systems

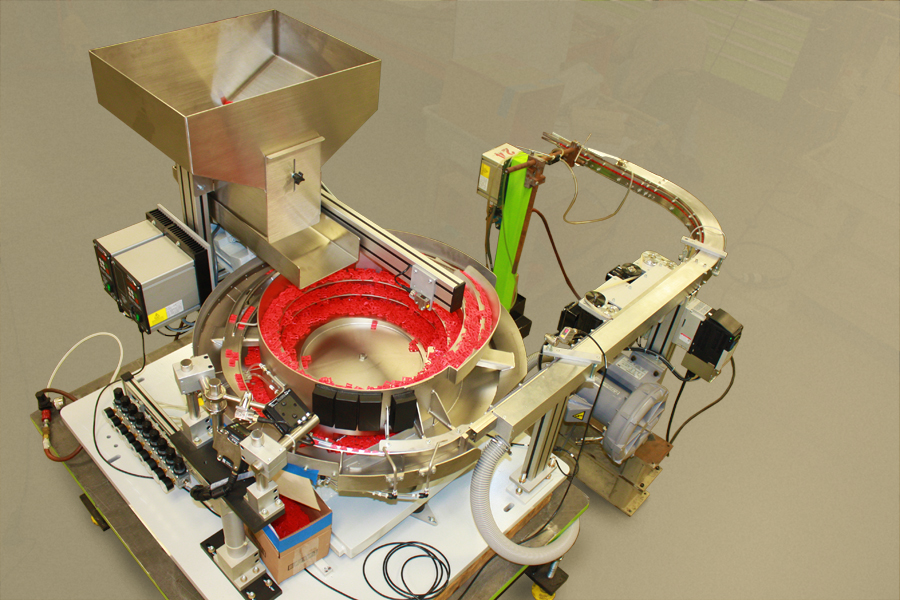

Problem: The manufacturer of plastic containers was in need of an automated feeder system for their closure components. They needed a high-speed system that would handle the molded plastic parts without clogging the machine while supplying their assembly lines at 200...

by Fortville Feeders | Jun 18, 2021 | Escapements and Mechanisms, Featured

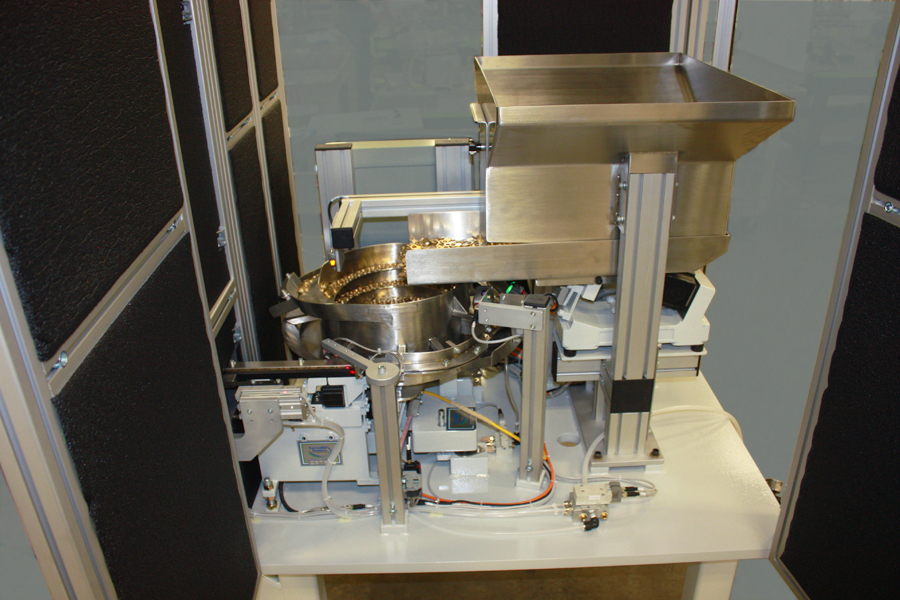

Problem: A manufacturer of hand-held outdoor equipment was in need of an automated parts feeding system that would lift bushing collars to three transfer stations on their assembly line. The three stations needed to operate independently of the other lines and supply...

Recent Comments