by Fortville Feeders | Aug 2, 2021 | Featured, Tracking Systems

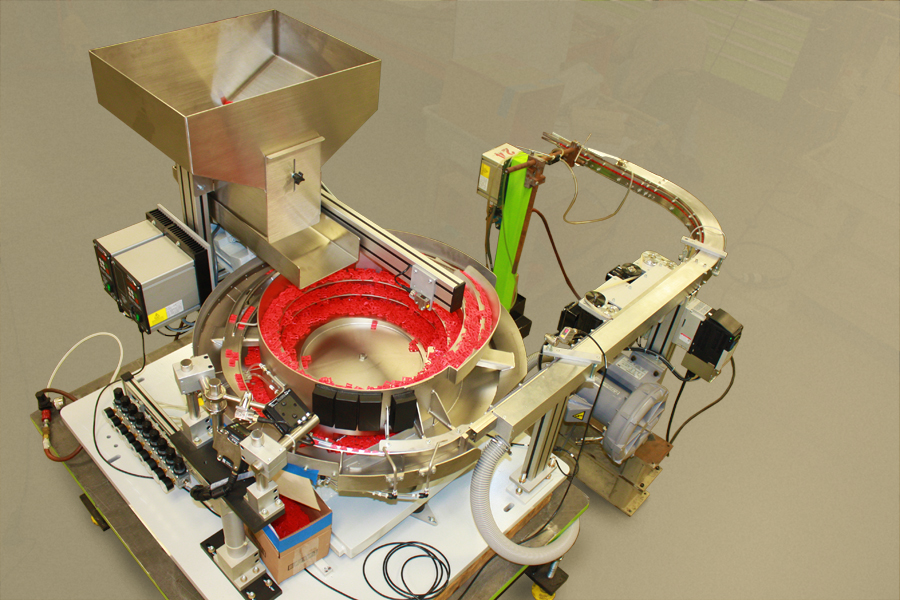

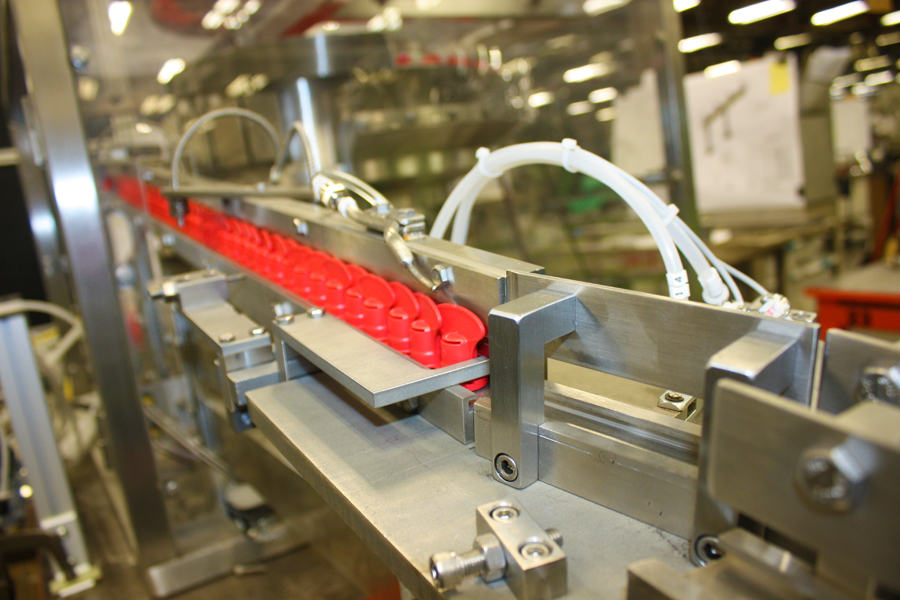

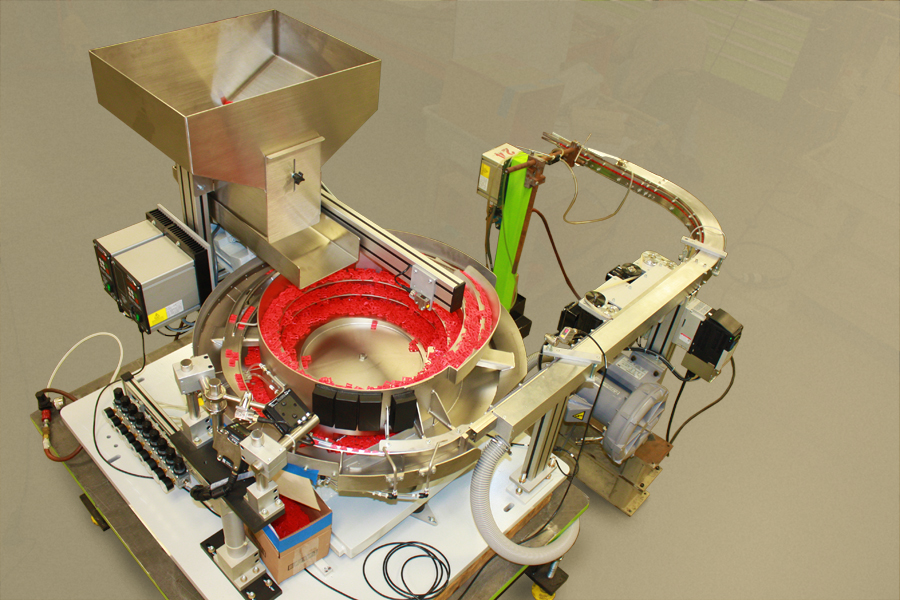

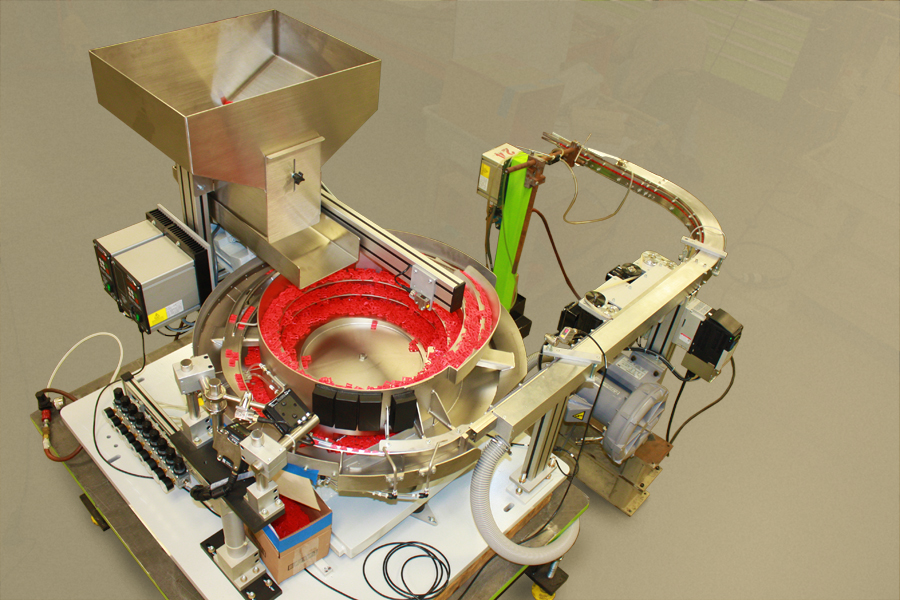

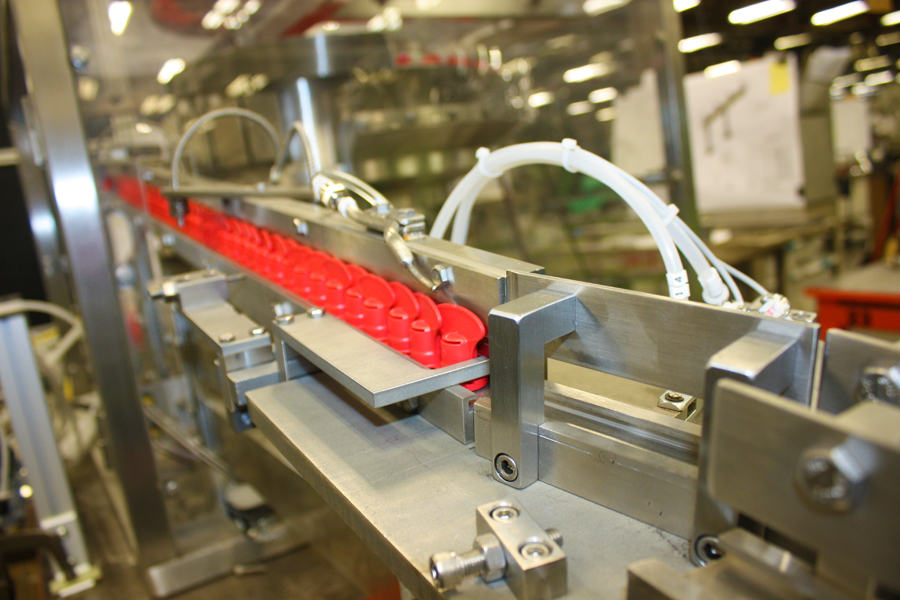

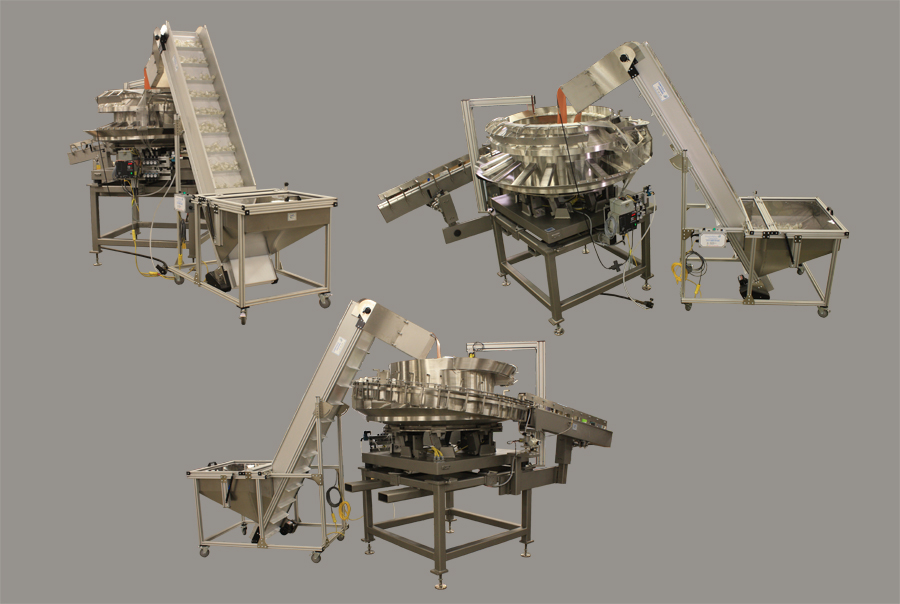

Problem: The manufacturer of plastic containers was in need of an automated feeder system for their closure components. They needed a high-speed system that would handle the molded plastic parts without clogging the machine while supplying their assembly lines at 200...

by Fortville Feeders | Jun 18, 2021 | Escapements and Mechanisms, Featured

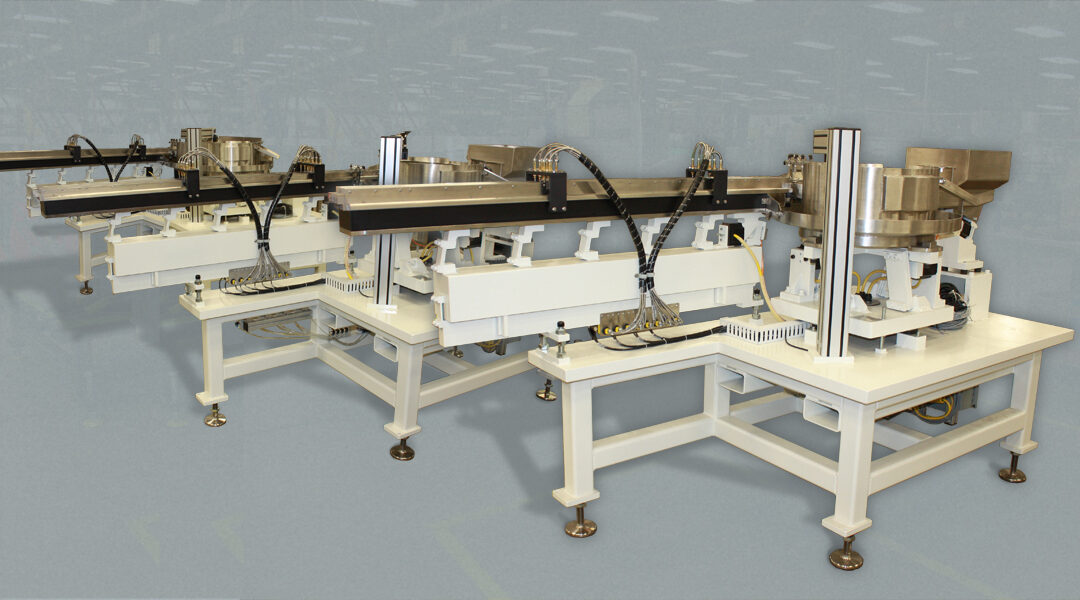

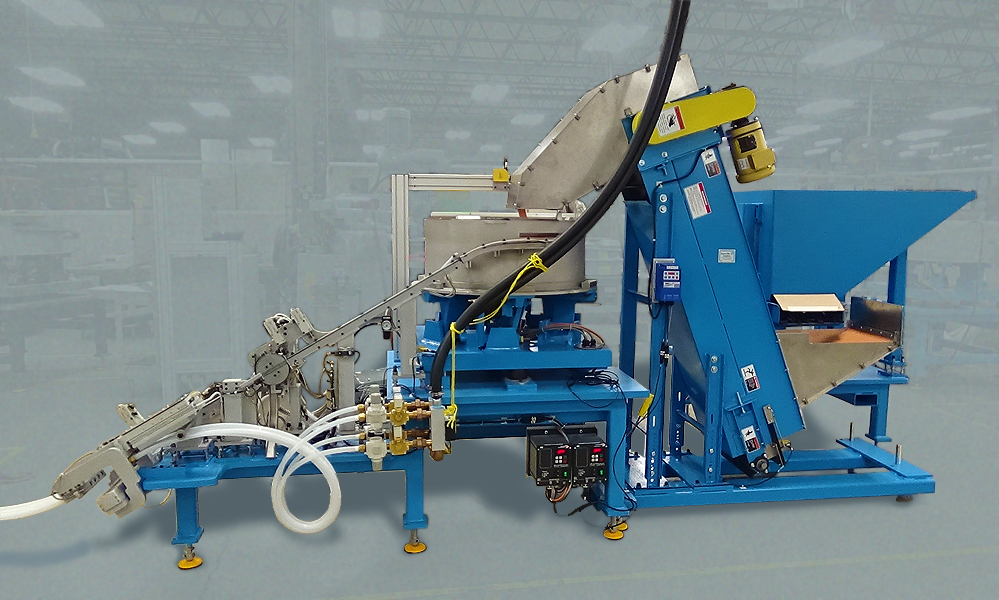

Problem: A manufacturer of hand-held outdoor equipment was in need of an automated parts feeding system that would lift bushing collars to three transfer stations on their assembly line. The three stations needed to operate independently of the other lines and supply...

by Fortville Feeders | May 17, 2021 | Featured, Tracking Systems

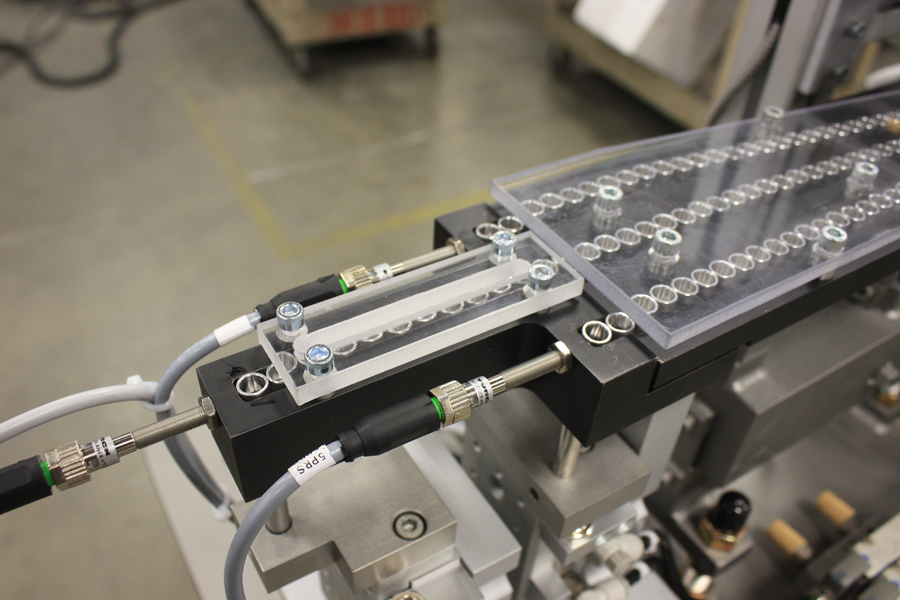

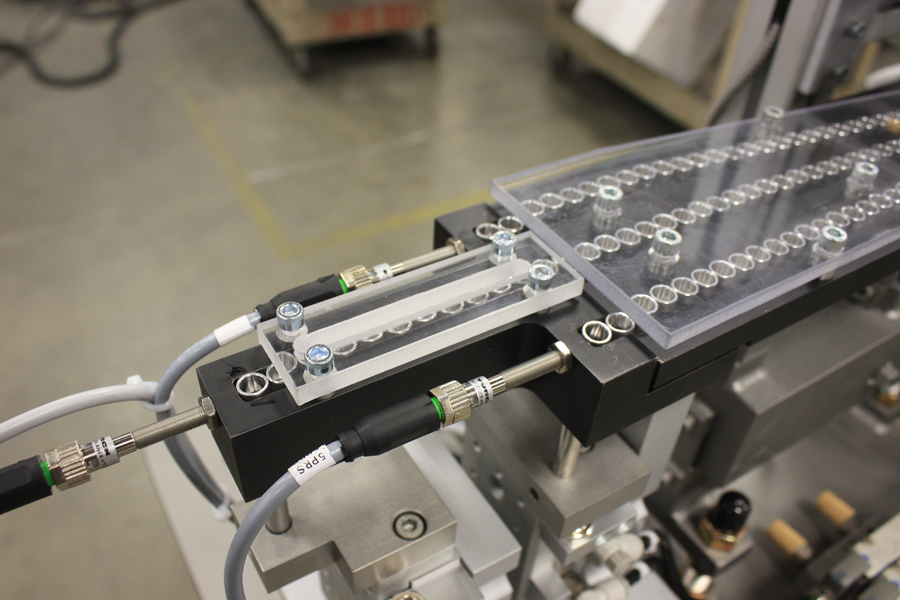

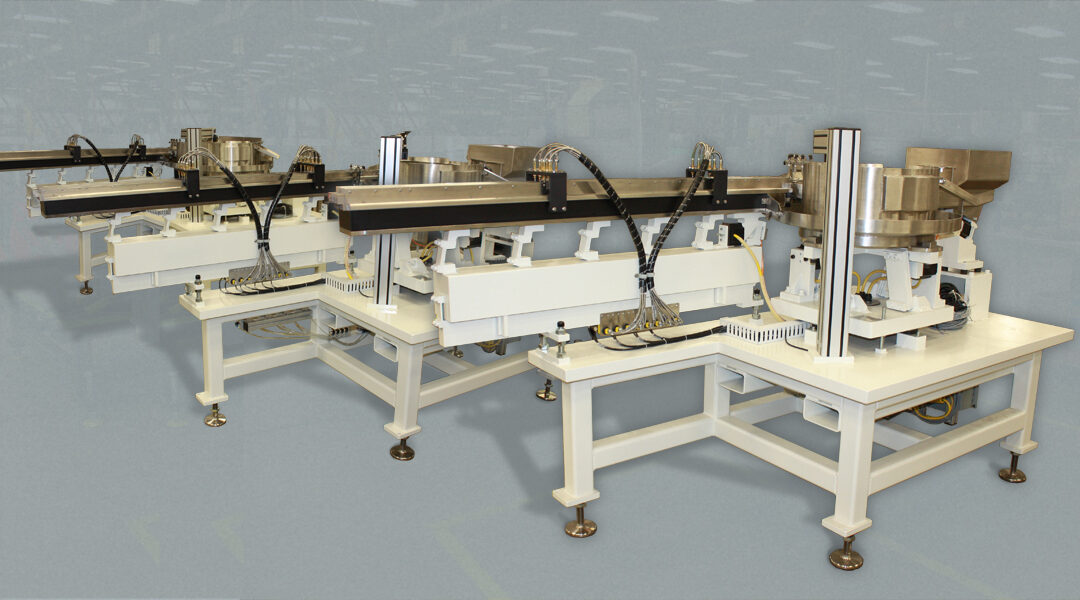

Problem: An automated machine builder that specialized in medical syringe assembly and packaging was in need of three identical feeder machines to handle needle holders. The parts were lightweight, very small (1 mm and 3mm widths) and needed to be fed at a rate of 54...

by Kevin Yaney | Mar 25, 2021 | Featured, Tracking Systems

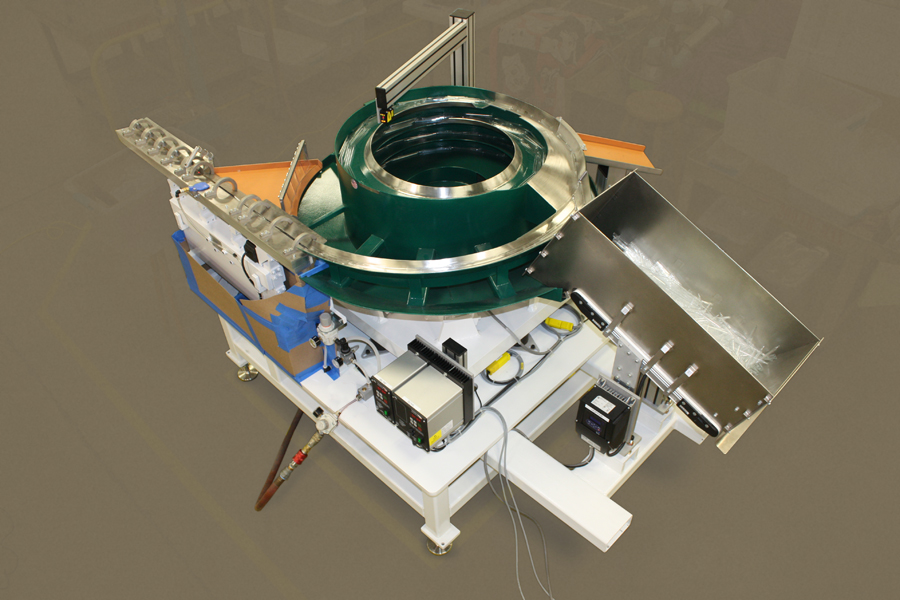

Problem: An integrator was building an automated system that packaged five different sizes of medical glass pipettes. The pipettes were very fragile and had to be gently handled, but delivered at 80 parts per minute. This included bulk loading of the parts, moving...

by Fortville Feeders | Mar 4, 2021 | Featured, Tracking Systems

Problem: A medical liquids bottler had a capping machine that used a Fortville Feeders designed parts feeder. The bottler made some changes to their bottling automation and needed a system that fed two lines instead of one. They approached Fortville Feeders to...

by Fortville Feeders | Feb 12, 2021 | Escapements and Mechanisms, Featured

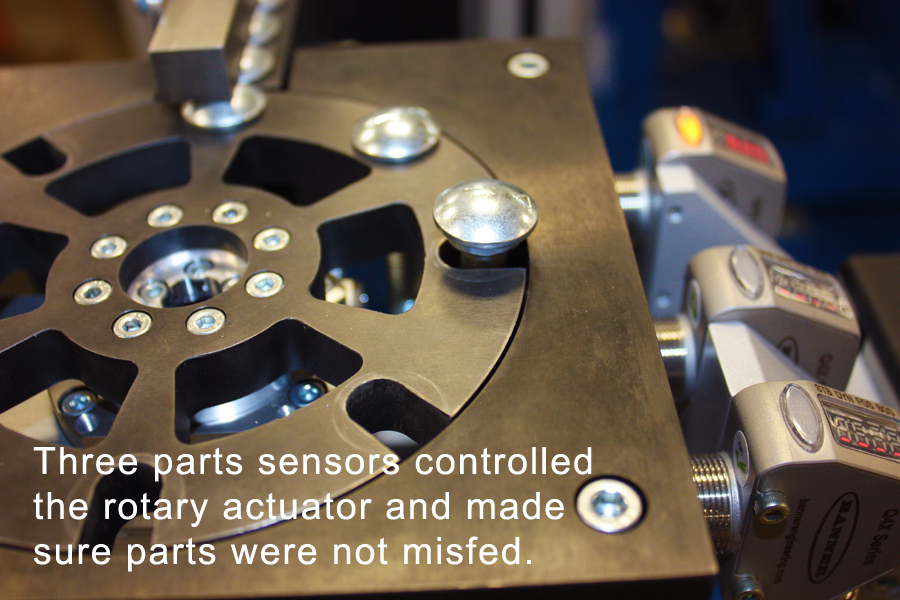

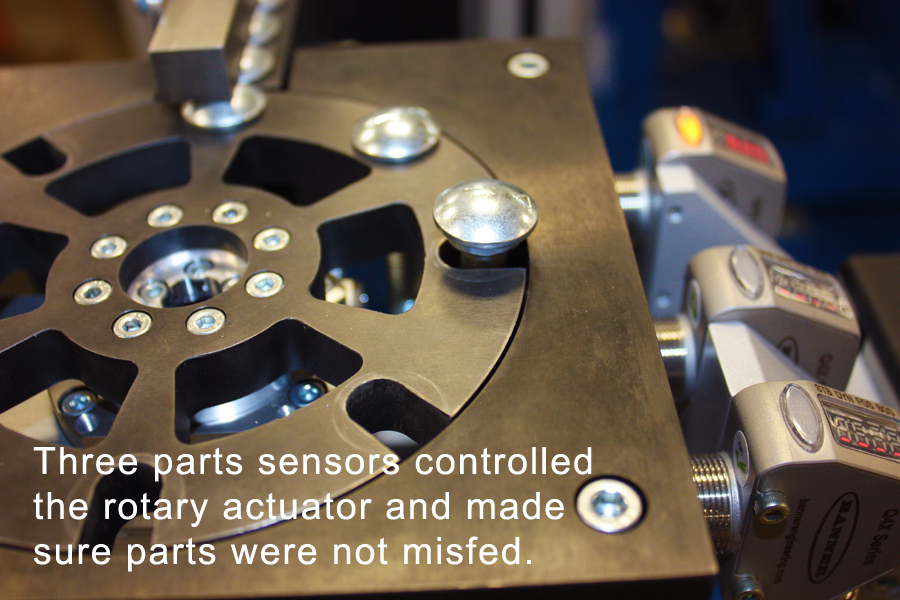

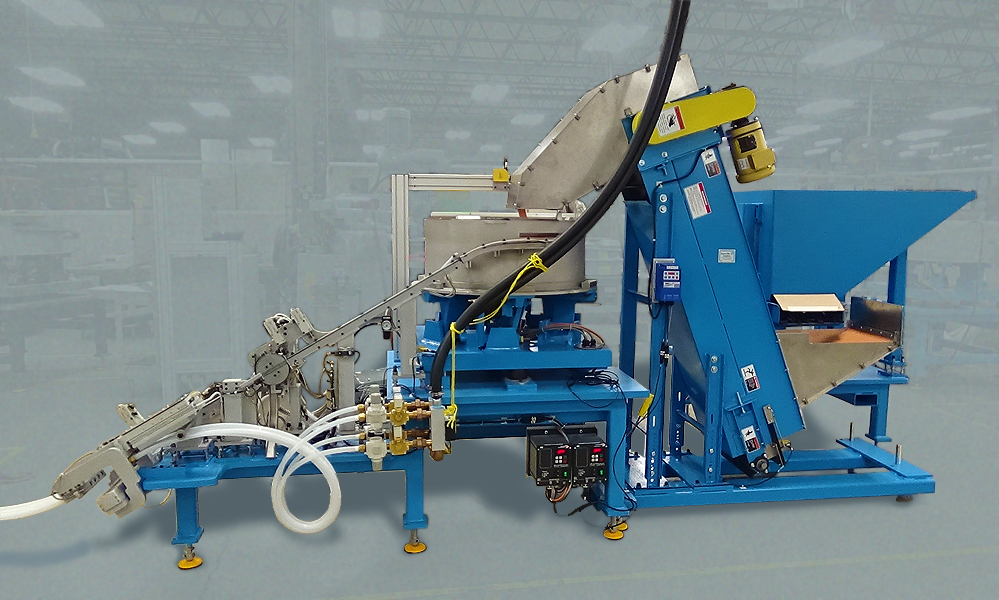

Problem: An integrator was building an automated assembly system for a manufacturing customer. They needed a parts feeder for a heavy metal fastener that was picked up by a robotic arm and assembled. There were two issues of concern. First, the part had to be...

by Fortville Feeders | Jan 15, 2021 | Escapements and Mechanisms, Featured

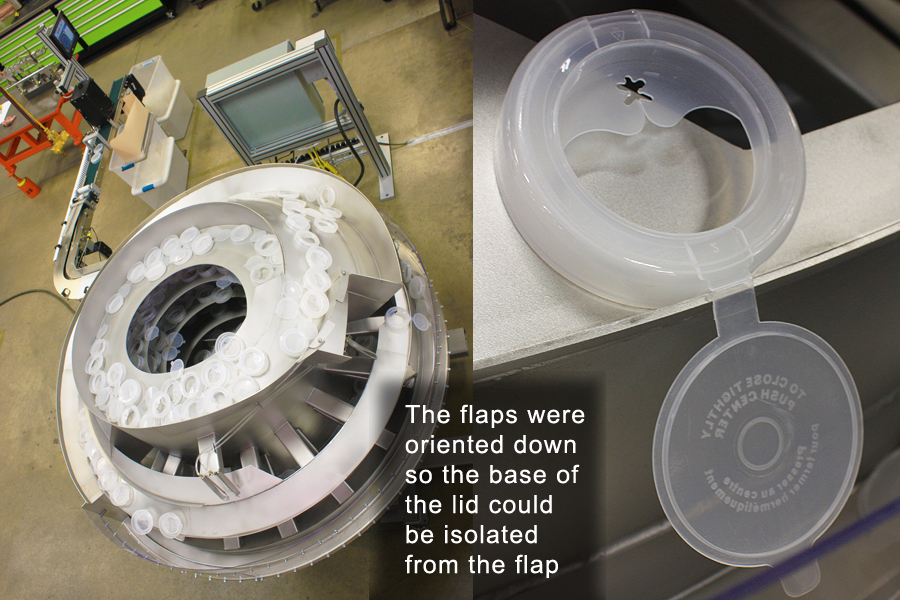

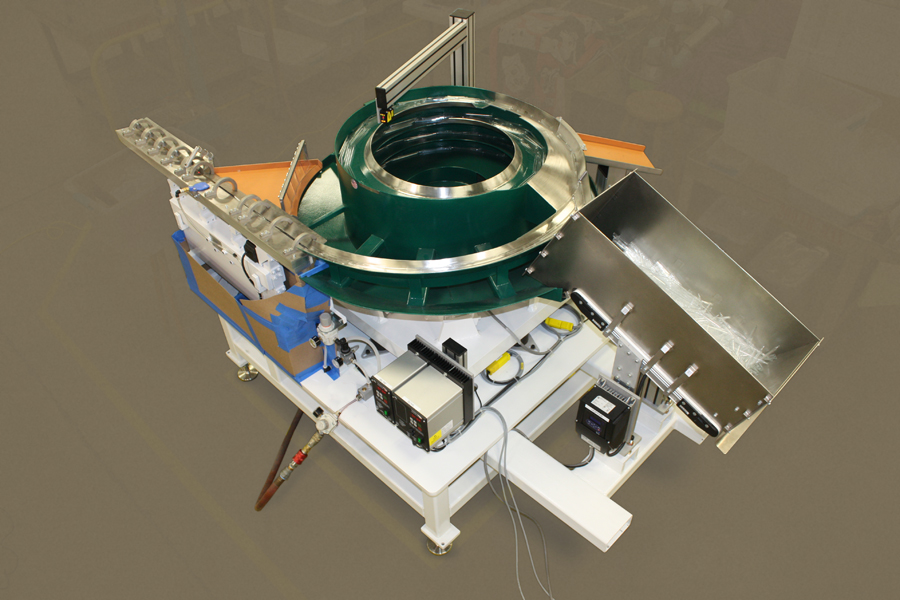

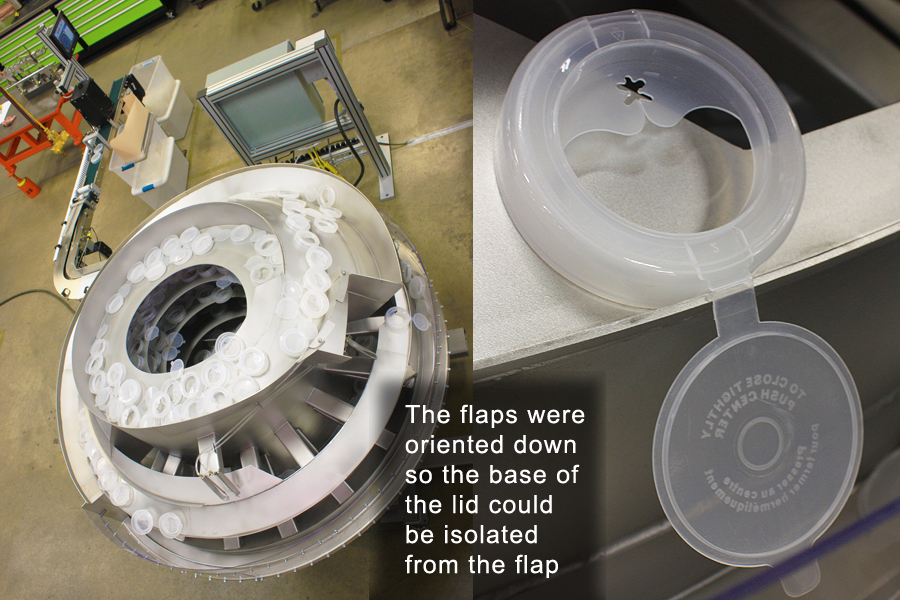

Problem: A packaging manufacturer for disinfectant wipes needed to develop a new feeder system to handle their double seal lids. Demand for the product made it necessary to build a new line. The plastic lids were required to be fed at a high rate to the customer’s...

by Fortville Feeders | Nov 13, 2020 | Featured, Tracking Systems

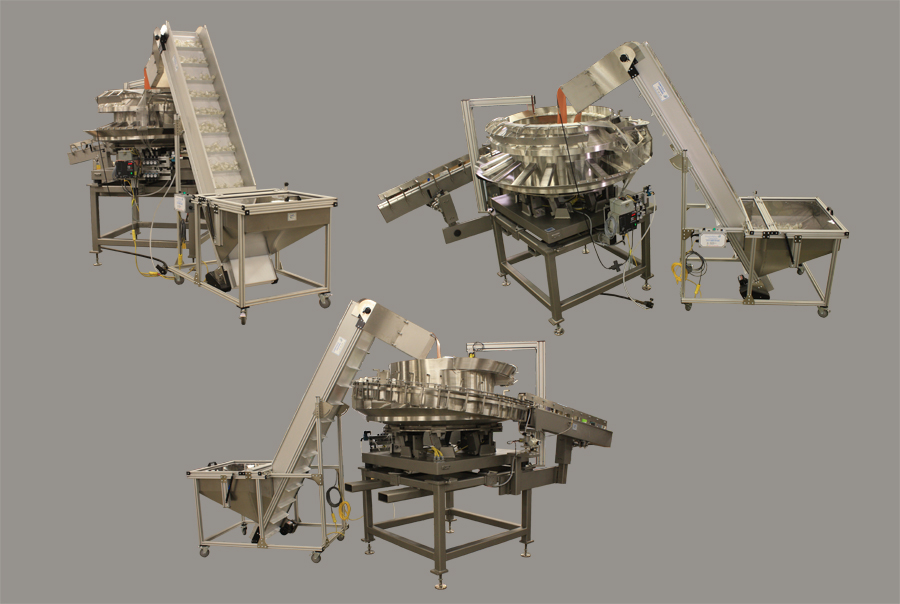

Problem: The manufacturer of hand sanitizer bottles desired a single feeder system for multiple foaming pump nozzles for their automated bottling assembly station. They had five different pump nozzles that were of different sizes and geometries. Some of these pump...

by Fortville Feeders | Oct 20, 2020 | Escapements and Mechanisms

Problem: A manufacturer of auto engine components was having trouble finding enough qualified laborers to assemble their solenoid housing units. They wished to automate the pre-welding assembly of two parts. These had previously been hand assembled before being picked...

by Fortville Feeders | Sep 29, 2020 | Escapements and Mechanisms

Problem: The customer was an integrator working for a manufacturer of heavy truck axles. They needed a parts feeder system for their assembly automation that would be able to handle three different axle studs. Each was of a different length. Each of the studs had a...

Recent Comments